Subtotal: ₹66,825.00

Product Carousel Tabs

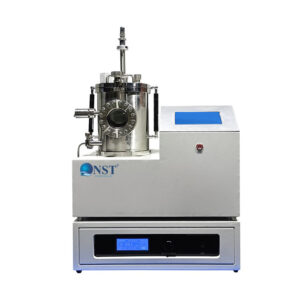

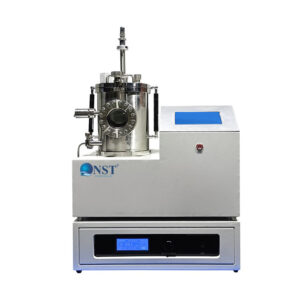

Desktop single target DC magnetron sputtering coater with stainless steel Chamber

Desktop single target DC magnetron sputtering coater with stainless steel Chamber

This equipment is a single-target magnetron sputtering coater, it can be used in the preparation of metal film, and also used in electronic fields, optical fields, special field of ceramic preparation ,it surely can be used in SEM sample preparation in laboratory.

Portable 50/100/200W Cleaning Machine Fiber Derusting Machine for Metal Stainless Steel Mechanical Parts

Portable 50/100/200W Cleaning Machine Fiber Derusting Machine for Metal Stainless Steel Mechanical Parts

Key attributes

Key Selling Points: Easy To Operate

Packaging and delivery

Atmospheric Direct Injection Plasma Cleaning Machine, Glass Plasma Surface Treatment

Atmospheric Direct Injection Plasma Cleaning Machine, Glass Plasma Surface Treatment

Key attributes

Key Selling Points : Easy To Operate

Packaging and delivery

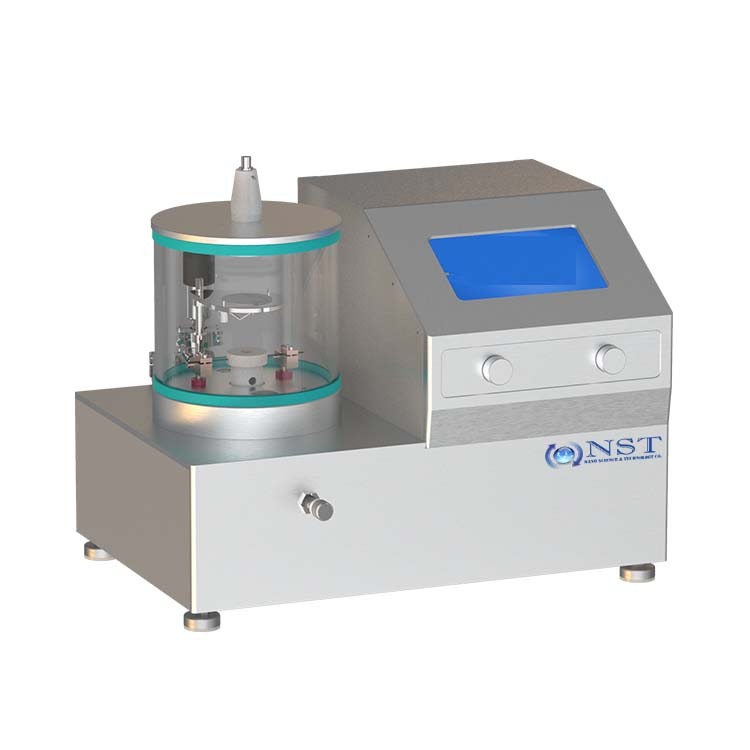

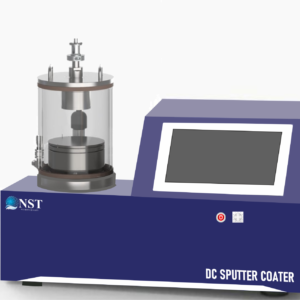

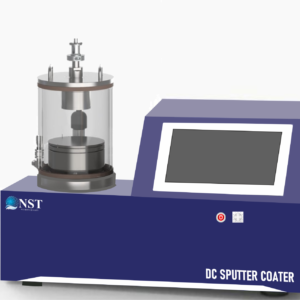

‘NST’ Desktop Plasma Sputtering Coater with Rotary Sample Stage Model: NST-PSC-180M (Manual)

‘NST’ Desktop Plasma Sputtering Coater with Rotary Sample Stage Model: NST-PSC-180M (Manual)

This type of small plasma sputtering coating machine adopts two-stage sputtering method, which is widely used for SEM sample preparation or metal coating experiment. Using low-temperature plasma sputtering process, there is no high temperature during the coating process, and it is not easy to produce thermal damage.

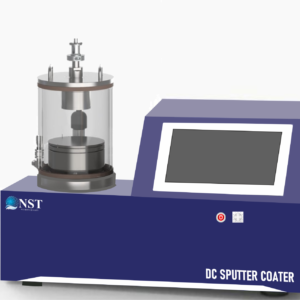

‘NST’ Desktop plasma sputtering coater with rotary sample stage NST-PSC180R

‘NST’ Desktop plasma sputtering coater with rotary sample stage NST-PSC180R

This type of small plasma sputtering coating machine adopts two-stage sputtering method, which is widely used for SEM sample preparation or metal coating experiment. Using low-temperature plasma sputtering process, there is no high temperature during the coating process, and it is not easy to produce thermal damage.

Analogue Penning Gauge

Penning gauge is a cold cathode Ionisation gauge consisting of two electrodes anode and cathode in side sensor. A potential difference of about 2.2 KV is applied between anode and cathode through current limiting resistors. A magnetic field is introduced at right angles to the plane of the electrodes by a permanent magnet which will increase the ionisation current. The electrons emitted from the cathode (gauge head body) of the gauge head are deflected by means of magnetic field applied at right angles to the plane of the electrodes and are made to take helical path before reaching the anode loop. Thus following very long path, the chance of collision with gas molecule is high even at low pressures. The secondary electrons produced by ionisation themselves perform similar oscillations and the rate of ionisation increases rapidly. Eventually, the electrons are captured by the anode and equilibrium is reached when the number of electrons produced per second by ionisation is the sum of positive ion current to the cathode and the electron current to the anode and is used to measure the pressure of the gas. This instrument with the sensor having wider range of applications, in high vacuum systems where the final Vacuum to be measured in process chamber.

Digital Penning Gauge

Penning gauge is a cold cathode Ionisation gauge consisting of two electrodes anode and cathode in side sensor. A potential difference of about 2.2 KV is applied between anode and cathode through current limiting resistors. A magnetic field is introduced at right angles to the plane of the electrodes by a permanent magnet which will increase the ionisation current. The electrons emitted from the cathode (gauge head body) of the gauge head are deflected by means of magnetic field applied at right angles to the plane of the electrodes and are made to take helical path before reaching the anode loop. Thus following very long path, the chance of collision with gas molecule is high even at low pressures. The secondary electrons produced by ionisation themselves perform similar oscillations and the rate of ionisation increases rapidly. Eventually, the electrons are captured by the anode and equilibrium is reached when the number of electrons produced per second by ionisation is the sum of positive ion current to the cathode and the electron current to the anode and is used to measure the pressure of the gas. This instrument with the sensor having wider range of applications, in high vacuum systems where the final Vacuum to be measured in process chamber.

Digital Pirani Gauge – Double Sensor – NST-D-2GH

The Vacuum Pirani Gauge Controller displays vacuum pressure as measured from a sensor tube. It displays vacuum measurements based on thermal conductivity of air or nitrogen. The Model DHPG controller covers the range from 0.001bar to 1000 mbar, and controls relay with independent set point.

Digital Pirani Gauge – Single Sensor – NST-D-1GH

The Vacuum Pirani Gauge Controller displays vacuum pressure as measured from a sensor tube. It displays vacuum measurements based on thermal conductivity of air or nitrogen. The Model DHPG controller covers the range from 0.001bar to 1000 mbar, and controls relay with independent set point.

Analogue Pirani Gauge – Double Sensor – NST-A-2GH

The Vacuum Pirani Gauge Controller displays vacuum pressure as measured from a sensor tube. It displays vacuum measurements based on thermal conductivity of air or nitrogen. The Model DHPG controller covers the range from 0.001bar to 1000 mbar, and controls relay with independent set point.

KF-40 BLANK FLANGE

KF VACUUM FITTINGS AND FLANGES

KF vacuum fittings and flanges consist of two flanges coupled together by a centering ring with a O-ring and a clamp. With this kind of connection provides many advantages, such as easy and quick mounting, assembly without any tools, unlimited orientation and easy interchangeability.

The standard sizes for KF vacuum fittings and flanges are KF-10, KF-16, KF-25, KF-40, and KF-50 with flange sizes NW-10, NW-16, NW-25, NW-40, and NW-50.

KF vacuum fittings and flanges are includes KF clamp, KF claw clamp, KF centering ring, KF o-ring, KF blank flange, KF bored weld flange, KF socket weld flange, KF half nipple, KF full nipple, KF reducing conical, KF elbows, KF tees, KF 4-way crosses, KF reducing tees, KF reducing 4-way crosses, KF flange to hose nozzle and so on.

‘NST’ Desktop plasma sputtering coater with rotary sample stage NST-PSC180R

‘NST’ Desktop plasma sputtering coater with rotary sample stage NST-PSC180R

This type of small plasma sputtering coating machine adopts two-stage sputtering method, which is widely used for SEM sample preparation or metal coating experiment. Using low-temperature plasma sputtering process, there is no high temperature during the coating process, and it is not easy to produce thermal damage.

‘NST’ Desktop Plasma Sputtering Coater with Rotary Sample Stage Model: NST-PSC-180M (Manual)

‘NST’ Desktop Plasma Sputtering Coater with Rotary Sample Stage Model: NST-PSC-180M (Manual)

This type of small plasma sputtering coating machine adopts two-stage sputtering method, which is widely used for SEM sample preparation or metal coating experiment. Using low-temperature plasma sputtering process, there is no high temperature during the coating process, and it is not easy to produce thermal damage.

1000W 10L Plasma Pleaner NST-P10L-1000W

10L plasma cleaner is a compact, non-destructive cleaning device. The plasma cleaner uses low air pressure to excite plasma as a cleaning medium, thereby effectively avoiding secondary pollution caused by the liquid cleaning medium to the object to be cleaned.

1000W 2L plasma cleaner NST-P2L-1000W

The plasma cleaner is a compact, non-destructive cleaning device. The plasma cleaner uses low air pressure to excite plasma as a cleaning medium, thereby effectively avoiding secondary pollution caused by the liquid cleaning medium to the object to be cleaned.

1000W 5L Plasma Cleaner NST-P5L-1000W

5L plasma cleaner is a compact, non-destructive cleaning device. The plasma cleaner uses low air pressure to excite plasma as a cleaning medium, thereby effectively avoiding secondary pollution caused by the liquid cleaning medium to the object to be cleaned

100W/150W 10L Plasma Cleaner NST-P10L-100W

10L plasma cleaner is a compact, non-destructive cleaning device. The plasma cleaner uses low air pressure to excite plasma as a cleaning medium, thereby effectively avoiding secondary pollution caused by the liquid cleaning medium to the object to be cleaned

100W/150W 2L plasma cleaner NST-P2L-100/150W

Plasma cleaning machine divided into two types, atmospheric and vacuum; it is widely used in semi-conductor, PCB, medical diagnosis, elastomer industry, optical industry,etc.

NST generator has 40KHz, 13.56Mhz, and 2.45GHz. According to the usage, can choose the suitable NST.

100W/150W 5L plasma cleaner NST-P5L-100W

100W/150W 5L plasma cleaner NST-P5L-100W

5L plasma cleaner is a compact, non-destructive cleaning device. The plasma cleaner uses low air pressure to excite plasma as a cleaning medium, thereby effectively avoiding secondary pollution caused by the liquid cleaning medium to the object to be cleaned.

12″ Precision Auto Lapping/ Polishing Machine for Preparing Metallographic Samples NST-GP-1202

12″ Precision Auto Lapping/ Polishing Machine for Preparing Metallographic Samples NST-GP-1202

This machine is equipped with 12″ super flat lapping plate and can be used as a high precision lapping machine for polishing crystal components, semiconductor wafers, and ceramic substrates up to 4″ in diameter. It can be used as a standard grinding and polishing machine for preparing metallographic samples as well.

300W / 500W 10L Oxygen Plasma Cleaner NST-P10L-300W/500W

10L plasma cleaner is a compact, non-destructive cleaning device. The plasma cleaner uses low air pressure to excite plasma as a cleaning medium, thereby effectively avoiding secondary pollution caused by the liquid cleaning medium to the object to be cleaned

300W/500W 2L plasma cleaning machine NST-P2L-500W

Plasma cleaner is a compact, non-destructive cleaning device. The plasma cleaner uses low air pressure to excite plasma as a cleaning medium, thereby effectively avoiding secondary pollution caused by the liquid cleaning medium to the object to be cleaned.

Dual-Target Magnetron Sputtering Coater NST-MSP300S-RFDC

Dual-target magnetron sputtering coater is a cost-effective magnetron sputtering coating equipment independently developed by our company. It is standardized, modular and customizable. There are 1-inch or 2-inch magnetron targets for you to choose. Customers can choose the target according to the size of the substrate to be coated

Professional Compact Turbo Pump Station (Oil Or Dry Backup Pump Optional)- NST-80

Professional Compact Turbo Pump Station (Oil Or Dry Backup Pump Optional)- NST-80

Pump station NST-80, Compact oil or dry backup pump optional

The turbo pumping station is a piece of clean high (ultrahigh) obtaining equipment, and it is a vacuum obtaining system mainly consists of a molecular pump and a mechanical pump according to vacuum knowledge and principle. The products in this Specification include FJ-80, turbo pumping station, with corresponding pumping speed of 62L/s. The pumping speeds of the backing oil pumps are 0.5L/s, and the pump speeds of the backing dry pumps are 0.2L. These products are widely applied to the fields of surface analysis, accelerator technology, plasma technology, research laboratories, electric vacuum device manufacturing and other vacuum areas.

NST Small high vacuum two-in-one film coater

The plasma sputtering and evaporating two-in-one film coater is equipped with DC sputtering target and thermal evaporation assembly, which can be used not only for plasma sputtering, but also obtain carbon or other metal simple films by evaporation.

NST High Temperature 1800°C Elevating Lifting Furnace With Mini Chamber

KF-10 CENTERING RING with Viton O-RING

KF VACUUM FITTINGS AND FLANGES

KF vacuum fittings and flanges consist of two flanges coupled together by a centering ring with a O-ring and a clamp. With this kind of connection provides many advantages, such as easy and quick mounting, assembly without any tools, unlimited orientation and easy interchangeability.

The standard sizes for KF vacuum fittings and flanges are KF-10, KF-16, KF-25, KF-40, and KF-50 with flange sizes NW-10, NW-16, NW-25, NW-40, and NW-50.

KF vacuum fittings and flanges are includes KF clamp, KF claw clamp, KF centering ring, KF o-ring, KF blank flange, KF bored weld flange, KF socket weld flange, KF half nipple, KF full nipple, KF reducing conical, KF elbows, KF tees, KF 4-way crosses, KF reducing tees, KF reducing 4-way crosses, KF flange to hose nozzle and so on.

NST Dual chamber pulse laser coater

NST Dual chamber pulse laser coater consists of vacuum chamber (main sputtering chamber, sample inlet chamber), sample transfer mechanism, sample frame, rotating target table, vacuum exhaust, vacuum measurement, electrical control, gas distribution, computer control and other parts.

Three Target Heads Plasma Sputtering Coater NST-PSP180G-3TA

Three target heads plasma sputtering coater is a cost-effective plasma sputter coating equipment independently developed by our company. It has the advantages of compact structure, easy to use, high integration and strong sense of design

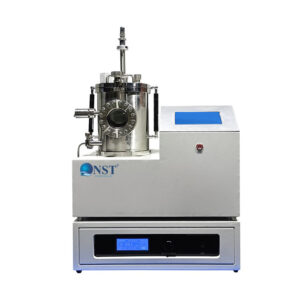

NST High vacuum magnetron sputtering coater

High vacuum magnetron sputtering coater is mainly composed of sputtering vacuum chamber, magnetron sputtering target, substrate water-cooled heating revolution table, working gas path, pumping system, installation machine, vacuum measurement and electronic control system.

12″ Precision Auto Lapping/ Polishing Machine for Preparing Metallographic Samples NST-GP-1202

12″ Precision Auto Lapping/ Polishing Machine for Preparing Metallographic Samples NST-GP-1202

This machine is equipped with 12″ super flat lapping plate and can be used as a high precision lapping machine for polishing crystal components, semiconductor wafers, and ceramic substrates up to 4″ in diameter. It can be used as a standard grinding and polishing machine for preparing metallographic samples as well.

NST High Temperture 1500C Two Zone Rotary Tube Furnace

Home Entertainment

-

Magnetron Sputtering coater

Magnetron Sputtering coater‘NST’ Desktop plasma sputtering coater with rotary sample stage NST-PSC180R

₹475,000.00 – ₹1,875,000.00 -

Planetary Ball Mills

Planetary Ball Mills‘NST’ 12L Lab Grinding Vertical Planetary Ball Mill Machine

₹519,750.00₹560,750.00

-

Planetary Ball Mills

Planetary Ball Mills‘NST’ 8L Lab Pigment Grinding Vertical Planetary Ball Mill Machine

₹650,000.00₹695,000.00 -

Planetary Ball Mills

Planetary Ball Mills‘NST’ 220V Bench-top 2L Vertical Lab Planetary Ball Mill Machine

₹550,000.00₹750,000.00

Laptops & Computers

-

Magnetron Sputtering coater

Magnetron Sputtering coater‘NST’ Desktop plasma sputtering coater with rotary sample stage NST-PSC180R

₹475,000.00 – ₹1,875,000.00

-

Planetary Ball Mills

Planetary Ball Mills‘NST’ 12L Lab Grinding Vertical Planetary Ball Mill Machine

₹519,750.00₹560,750.00

-

Planetary Ball Mills

Planetary Ball Mills‘NST’ 8L Lab Pigment Grinding Vertical Planetary Ball Mill Machine

₹650,000.00₹695,000.00 -

Planetary Ball Mills

Planetary Ball Mills‘NST’ 220V Bench-top 2L Vertical Lab Planetary Ball Mill Machine

₹550,000.00₹750,000.00

Trending Products

-

Magnetron Sputtering coater

Magnetron Sputtering coater‘NST’ Desktop plasma sputtering coater with rotary sample stage NST-PSC180R

₹475,000.00 – ₹1,875,000.00 -

Planetary Ball Mills

Planetary Ball Mills‘NST’ 12L Lab Grinding Vertical Planetary Ball Mill Machine

₹519,750.00₹560,750.00

-

Planetary Ball Mills

Planetary Ball Mills‘NST’ 8L Lab Pigment Grinding Vertical Planetary Ball Mill Machine

₹650,000.00₹695,000.00 -

Planetary Ball Mills

Planetary Ball Mills‘NST’ 220V Bench-top 2L Vertical Lab Planetary Ball Mill Machine

₹550,000.00₹750,000.00

Bestseller

-

Magnetron Sputtering coater

Desktop single target DC magnetron sputtering coater with stainless steel Chamber

Magnetron Sputtering coater

Magnetron Sputtering coaterDesktop single target DC magnetron sputtering coater with stainless steel Chamber

This equipment is a single-target magnetron sputtering coater, it can be used in the preparation of metal film, and also used in electronic fields, optical fields, special field of ceramic preparation ,it surely can be used in SEM sample preparation in laboratory.

SKU: n/a -

Atmospheric Plasma Cleaner/ Corona treater

Portable 50/100/200W Cleaning Machine Fiber Derusting Machine for Metal Stainless Steel Mechanical Parts

Atmospheric Plasma Cleaner/ Corona treater

Atmospheric Plasma Cleaner/ Corona treaterPortable 50/100/200W Cleaning Machine Fiber Derusting Machine for Metal Stainless Steel Mechanical Parts

Key attributes

Key Selling Points: Easy To Operate

Applicable Material: Stainless steelLaser Type: Fiber laserLaser Power: 50w/100w/200wCleaning speed: 5-15 m²/hCleaning width: 500-1200 mmwarranty: 1 Yearpower(w): 50w/100w/200wCooling system: Air coolingcondition: NewBrand name: NSTdimension(l*w*h): 50*50*50Weight: 50Packaging and delivery

Selling Units: Single itemSingle package size: 60.0X48.0X30.0 cmSingle gross weight: 28.000 kgSKU: n/a -

Atmospheric Plasma Cleaner/ Corona treater

Atmospheric Direct Injection Plasma Cleaning Machine, Glass Plasma Surface Treatment

Atmospheric Plasma Cleaner/ Corona treater

Atmospheric Plasma Cleaner/ Corona treaterAtmospheric Direct Injection Plasma Cleaning Machine, Glass Plasma Surface Treatment

Key attributes

Key Selling Points : Easy To Operate

Applicable Material: MetalLaser Type: Fiber LaserLaser Power: 1000 WCleaning speed: 1-10mmCleaning width: 1-10mmwarranty: 1 Yearpower(w):1000 WCooling system: Air coolingbrand name: NSTdimension(l*w*h): 1000*1000*1000Weight: 45 KGPackaging and delivery

Selling Units: Single itemSingle package size: 120.0X100.0X180.0 cmSingle gross weight: 45.000 kgSKU: n/a -

Magnetron Sputtering coater

‘NST’ Desktop Plasma Sputtering Coater with Rotary Sample Stage Model: NST-PSC-180M (Manual)

Magnetron Sputtering coater

Magnetron Sputtering coater‘NST’ Desktop Plasma Sputtering Coater with Rotary Sample Stage Model: NST-PSC-180M (Manual)

This type of small plasma sputtering coating machine adopts two-stage sputtering method, which is widely used for SEM sample preparation or metal coating experiment. Using low-temperature plasma sputtering process, there is no high temperature during the coating process, and it is not easy to produce thermal damage.

SKU: n/a -

Magnetron Sputtering coater

‘NST’ Desktop plasma sputtering coater with rotary sample stage NST-PSC180R

Magnetron Sputtering coater

Magnetron Sputtering coater‘NST’ Desktop plasma sputtering coater with rotary sample stage NST-PSC180R

This type of small plasma sputtering coating machine adopts two-stage sputtering method, which is widely used for SEM sample preparation or metal coating experiment. Using low-temperature plasma sputtering process, there is no high temperature during the coating process, and it is not easy to produce thermal damage.

SKU: n/a

Top Categories of this Month

Recommendation for you

Desktop single target DC magnetron sputtering coater with stainless steel Chamber

Desktop single target DC magnetron sputtering coater with stainless steel Chamber

This equipment is a single-target magnetron sputtering coater, it can be used in the preparation of metal film, and also used in electronic fields, optical fields, special field of ceramic preparation ,it surely can be used in SEM sample preparation in laboratory.

Portable 50/100/200W Cleaning Machine Fiber Derusting Machine for Metal Stainless Steel Mechanical Parts

Portable 50/100/200W Cleaning Machine Fiber Derusting Machine for Metal Stainless Steel Mechanical Parts

Key attributes

Key Selling Points: Easy To Operate

Packaging and delivery

Atmospheric Direct Injection Plasma Cleaning Machine, Glass Plasma Surface Treatment

Atmospheric Direct Injection Plasma Cleaning Machine, Glass Plasma Surface Treatment

Key attributes

Key Selling Points : Easy To Operate

Packaging and delivery

‘NST’ Desktop Plasma Sputtering Coater with Rotary Sample Stage Model: NST-PSC-180M (Manual)

‘NST’ Desktop Plasma Sputtering Coater with Rotary Sample Stage Model: NST-PSC-180M (Manual)

This type of small plasma sputtering coating machine adopts two-stage sputtering method, which is widely used for SEM sample preparation or metal coating experiment. Using low-temperature plasma sputtering process, there is no high temperature during the coating process, and it is not easy to produce thermal damage.

‘NST’ Desktop plasma sputtering coater with rotary sample stage NST-PSC180R

‘NST’ Desktop plasma sputtering coater with rotary sample stage NST-PSC180R

This type of small plasma sputtering coating machine adopts two-stage sputtering method, which is widely used for SEM sample preparation or metal coating experiment. Using low-temperature plasma sputtering process, there is no high temperature during the coating process, and it is not easy to produce thermal damage.

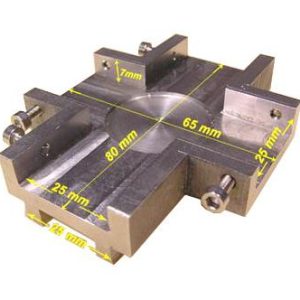

Precision Cross Mount Vise for EC400 dicing and 150 Low Speed

Precision Cross Mount Vise for EC400 dicing and 150 Low Speed