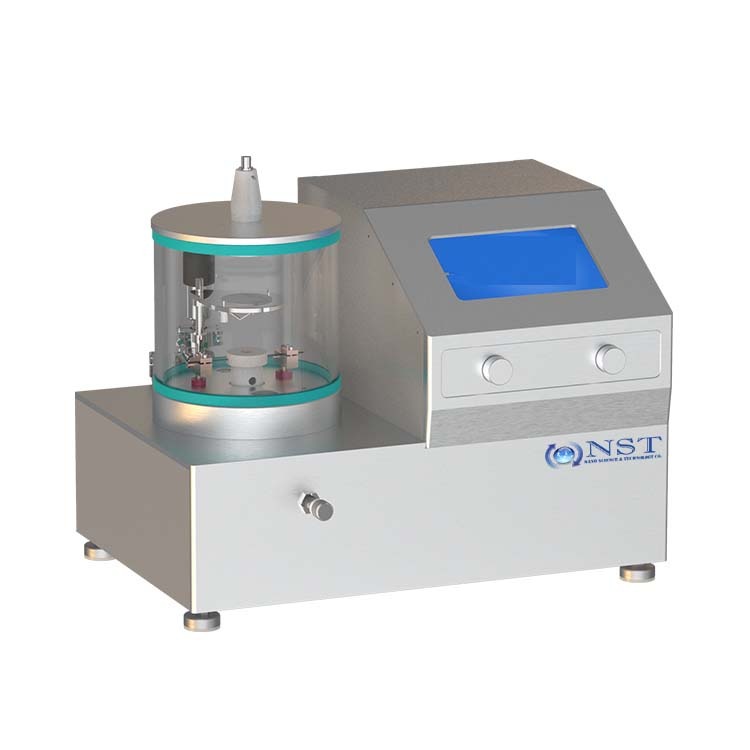

NST-in-line magnetron sputtering system

NST-in-line magnetron sputtering system is used to deposit metal film (Al, Ag, Ni, Cu, Ti, Pd, etc.) on the surface of crystal silicon, and can realize reactive sputtering. It can complete magnetron sputtering process under high and low vacuum, and also has the ability to produce crystalline silicon photovoltaic film in various sizes and larg.

₹6,100,000.00 ₹6,500,000.00

TECHNICAL PARAMETER

NST-in-line magnetron sputtering system mainly consists of a loading sample chamber, a sputtering chamber, a output sample chamber, a substrate transfer mechanism, a pumping and vacuum measuring system, a gas circuit system, an electronic control system, and a mounting base. In addition, after the system is upgraded, it would be a 5 chamber structure: the loading sample chamber, 3 independent sputtering chambers, output sample chamber; Rf power supply is added to provide the function of preparing dielectric film and realize continuous coating.

NST-in-line magnetron sputtering system specifications:

| Main sputtering chamber | Square vacuum chamber, size: 1000×700×350mm | |

| Loading samplechamber | Cylindrical, bed chamber, dimension: 250×420mm | |

| Vacuum system | Molecular pump, mechanical pump, gate valve | |

| Ultimate pressure | Main sputtering chamber | ≤8×10-5Pa (after baking degassing) |

| Loading sample chamber | ≤6.6×10-4Pa (after baking degassing) | |

| Vacuum

recovery time |

Main sputtering chamber | Can reach 6.6×10-4Pa in 40 mins (The system exposed the atmosphere for a short time and filled with dry nitrogen to start pumping) |

| Loading sample chamber | Can reach6.6×10-3Pa in 20 mins (The system exposed the atmosphere for a short time and filled with dry nitrogen to start pumping) | |

| Magnetic target component | Rectangular target size: 450×45 mm | |

| Distance between target and sample: 80mm adjustable | ||

| Substrate heating platform | Substrate size | 125×125mm or 156×156mm, 4 samples can be installed at one time |

| Heating temperature | Room temperature: 400℃±2℃, adjustable | |

| Gas circuit system | Mass flow controller 3 circuits | |

| Space occupied | Main unit | 2655×930mm² |

| Electric cabinet | 700×700mm² (Two) | |

| After-sales service | after the goods are delivered, CYKY provides one year of free after-sales service. The service method is limited to remote technical support such as telephone guidance, video guidance, mail guidance, and accessories mailing. If the customer needs to send someone to provide door-to-door service, the customer shall pay the travel expenses and wages of the service personnel during the business trip. | |

Disclaimer: The product introduction content (including product images, product descriptions, technical parameters, etc.) of this site is for reference only. As the update may not be timely, there will be some differences between the content and the actual situation. Please contact our sales staff to confirm. The information provided on this site does not constitute any offer or promise, and the company will periodically improve and modify the website information, without prior notice, please understand.

There are no reviews yet.