Subtotal: ₹889,225.00

Small Stirred Ball Mill

Application:It’s widely applied in fields of zirconia silicate, zirconia, alumina oxide, ceramic, chemical, electronic material, magnetic material, paper-making, painting, non-metal minerals, new materials, coating, graphite, calcium carbonate, medicine, and so on.

Compare

Stirred ball mill mainly consist of jar with inner grinding media, stirring device and other auxiliary devices such as recycling device, cooling device, timing device, speed adjusting controller, and etc. Its advantages of high efficiency and fine granularity meet technological requirements of various processes. Stirred ball mill is a kind of ideal equipment that are used to crush new materials and research painting for universities, research centers and enterprises because of its features of small batch, low power and low price.

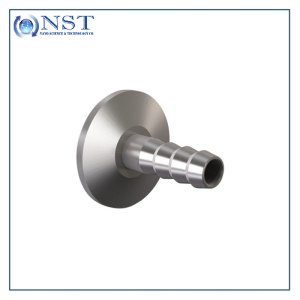

KF-50 FLANGE TO HOSE NOZZLE

KF-50 FLANGE TO HOSE NOZZLE  Vacuum Rapid Heated Pressing Furnace up to NST 1600℃

Vacuum Rapid Heated Pressing Furnace up to NST 1600℃  Heavy Duty Coolant Circulating Tank with Pump, 4 L for MTI Cutting saw

Heavy Duty Coolant Circulating Tank with Pump, 4 L for MTI Cutting saw

There are no reviews yet.