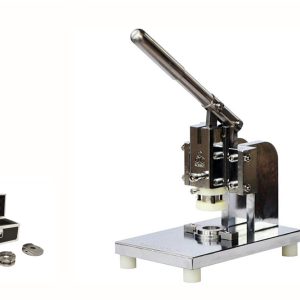

MSK-180SP is a gas driven die cutter for producing pouch battery cathode/anode electrodes ( no electricity required ) Its compact design enables the operation inside a glove box with Ar atmosphere where moisture/oxygen-sensitive electrodes will be cut (such as lithium metal electrode for Lithium-Sulfur, Lithium Air, and Lithium Solid State batteries).

SPECIFICATIONS:

| Die Set Dimensions

|

- Two standard electrodes (Cathode & Anode) cutting dies are included for immediate use.

- Cathode Die: 56mm (L) x 43mm (W). With 10mm (L) x 10mm (W) protrude current collector.

- Anode Die: 58mm (L) x 45mm (W). With 10mm (L) x 10mm (W) protrude current collector

- Customized dies with Max. area 80mm L x 60mm W, including current collector, available at extra cost.

|

| Plate Pad |

- Use the plate pad to hold the electrode and minimize permanent markings on the base.

Warning: please don’t use other material to replace the pad Warning: please don’t use other material to replace the pad

|

| Cutting Depth |

Max. 0.5mm (tested with aluminum laminated film) |

| Cutting Accuracy |

±0.1mm |

| Cutting Pressure Force |

Max. 1T (recommended pressure force for cutting battery electrodes is 0.5T) |

Glove Box Compatibility

|

- KF40 Feedthrough with all necessary wire and tube are included to allow operating inside the Glove box, which has a KF40 port (Click on the first and second pictures for details)

- Please use Inert gas when operating in the glove box.

- One KF-40 Clamp with rubber O-ring is included

|

| Gas Pressure |

- 0.5~1.0Mpa (0.7Mpa is recommended)

- For the use of inside the glove box, please use compressed inert gas such as Ar.

- For the use of outside the glove box, you may use the air compressor, 60 psi recommended.

- Compressor is not included, please click the image on the left to order

- Attention: If a gas cylinder is used instead of air compressor(pic2), a two-stage pressure regulator(pic1) must be installed on the gas cylinder to limit the pressure within the required working range for safe operation. Click here to learn the installation of a gas regulator.

pic1 pic1  pic2 pic2 |

| Feeding |

Manually |

| Stroke Length |

12mm |

| Cutting Die Life Span |

~30000 strokes |

| Compliance |

- CE Certified

- No UL required because of no electricity

|

| Warranty |

One Year limited warranty with lifetime support |

| Operation Manual & Video

|

How to cut electrode How to make pouch Cell Li-S Line in glovebox How to make single layer pouch cell

|

| Product Dimensions |

370mm(L) x 250mm(W) x 245mm(H) 370mm(L) x 250mm(W) x 245mm(H) |

| Optional |

- You may order pre-formed pouch cell case and other accessories by click picture below right

- You might order round cutting die kit to cut coin cell electrodes and separator by click picture below:

- Please consider 3 in1 sealing machine to make pouch cell.

-

|

| Application Notes |

- A Perfect fit for the cases formed by the standard size MSK-120, with no rough edge, clippings, or creasings

- The shape of the electrodes it produces is also handy for the later processing steps such as tab welding by MSK-800 and electrode stacking by MSK-111A.

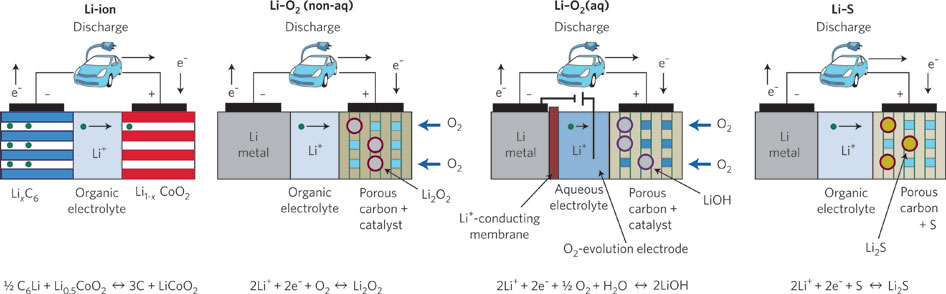

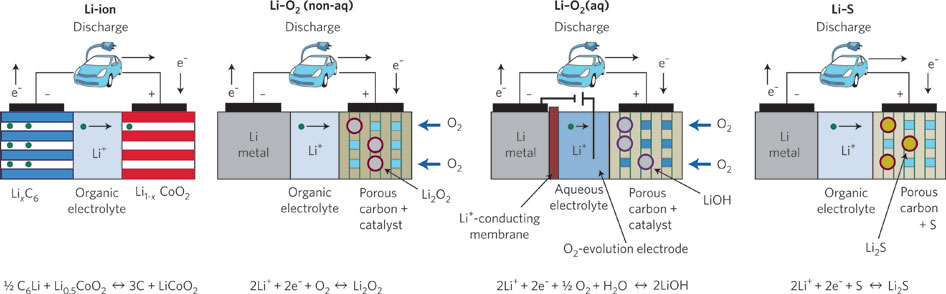

- Compact design enables the operation inside the glove box with Ar atmosphere where Lithium Sulfur, Lithium Air, Lithium Solid State or Li-ion half cell will be assembled. Please click the images in below to understand these technologies and how it fits in a glove box.

|

| Net Weight |

32kg |

| Shipping Weight & Dimensions |

110 lbs; 40″ x 25″ x 20″ |

370mm(L) x 250mm(W) x 245mm(H)

370mm(L) x 250mm(W) x 245mm(H)

There are no reviews yet.