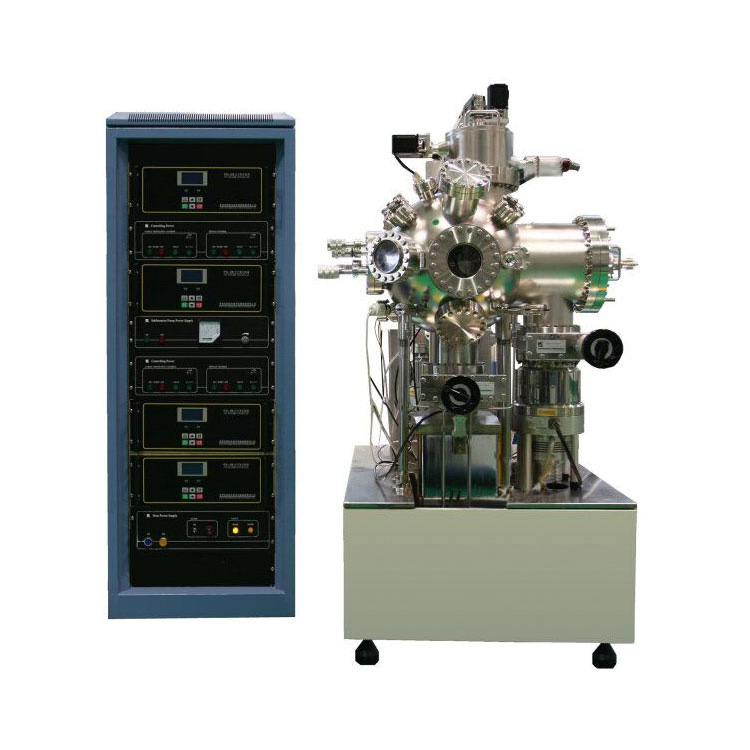

NST Dual chamber pulse laser coater

NST Dual chamber pulse laser coater consists of vacuum chamber (main sputtering chamber, sample inlet chamber), sample transfer mechanism, sample frame, rotating target table, vacuum exhaust, vacuum measurement, electrical control, gas distribution, computer control and other parts.

₹1.00

CompareTECHNICAL PARAMETER

NST Dual chamber pulse laser coater is used for growing optical crystals, ferroelectrics, ferromagnets, superconductors and organic compound thin film materials, suitable for growing high melting point, multi-elements and complex layered superlattice thin film materials containing gas elements. It is widely used in the research and manufacture of thin film materials in colleges and universities.

Dual chamber pulse laser coater specifications:

| Main vacuum system | Sphere structure, size:Ø 450mm | |

| Loading sample system | Vertical cylindrical stucture, size: Ø 150×150mm | |

| Vacuum system configuration | Main vacuum chamber | Mechanical pump, molecular pump, valve |

| Loading sample system | Mechanical pump and molecular pump(sharing with primary chamber), valve | |

| Ultimate pressure | Main vacuum system | ≤6*10-6Pa(after baking and degassing) |

| Loading sample system | ≤6*10-3 Pa(after baking and degassing) | |

| Vacuum recovery system | Main vacuum system | It can reach 5×10-3Pa in 20 minutes (the system is exposed to the atmosphere for a short time and filled with dry nitrogen to start pumping) |

| Loading sample system | It can reach 5×10-3Pa in 20 minutes (the system is exposed to the atmosphere for a short time and filled with dry nitrogen to start pumping) | |

| Rotating target platform | The maximum size of the target is about 60mm. Four target materials can be installed at one time, target changing in revolution motion; each target can rotate independently, rotation speed: 5-60 rpm | |

| Substrate heating platform | Sample size | Ø51 |

| Mode of motion | Substrate rotates continuously, rotation speed:5-60 rpm | |

| Heating temperature | Maximum temperature of substrate heating: 800℃±1℃, Controlled and adjustable | |

| Gas circuit system | 1-circuit mass flow controller, 1-circuit inflation valve | |

| Optional accessories | Laser device | Compatible with coherent 201 laser |

| Laser beam scanning device | 2D scanning mechanical platform, perform two degree of freedom scanning. | |

| Computer control system | The contents of control include common conversion target, target rotation, sample rotation, sample temperature control, laser beam scanning, etc. | |

| Space occupied | Main unit | 1800 * 1800mm2 |

| Electric cabinet | 700 *700mm2(one) | |

Disclaimer: The product introduction content (including product images, product descriptions, technical parameters, etc.) of this site is for reference only. As the update may not be timely, there will be some differences between the content and the actual situation. Please contact our sales staff to confirm. The information provided on this site does not constitute any offer or promise, and the company will improve and modify any information on the website from time to time without prior notice.

There are no reviews yet.