Deals of The Day

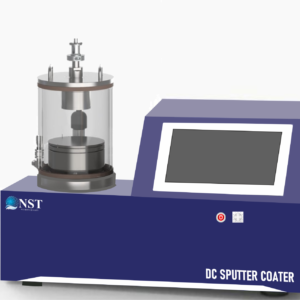

‘NST’ Desktop plasma sputtering coater with rotary sample stage NST-PSC180G

This type of small plasma sputtering coating machine adopts two-stage sputtering method, which is widely used for SEM sample preparation or metal coating experiment. Using low-temperature plasma sputtering process, there is no high temperature during the coating process, and it is not easy to produce thermal damage.

Analogue Penning Gauge

Penning gauge is a cold cathode Ionisation gauge consisting of two electrodes anode and cathode in side sensor. A potential difference of about 2.2 KV is applied between anode and cathode through current limiting resistors. A magnetic field is introduced at right angles to the plane of the electrodes by a permanent magnet which will increase the ionisation current. The electrons emitted from the cathode (gauge head body) of the gauge head are deflected by means of magnetic field applied at right angles to the plane of the electrodes and are made to take helical path before reaching the anode loop. Thus following very long path, the chance of collision with gas molecule is high even at low pressures. The secondary electrons produced by ionisation themselves perform similar oscillations and the rate of ionisation increases rapidly. Eventually, the electrons are captured by the anode and equilibrium is reached when the number of electrons produced per second by ionisation is the sum of positive ion current to the cathode and the electron current to the anode and is used to measure the pressure of the gas. This instrument with the sensor having wider range of applications, in high vacuum systems where the final Vacuum to be measured in process chamber.

Digital Penning Gauge

Penning gauge is a cold cathode Ionisation gauge consisting of two electrodes anode and cathode in side sensor. A potential difference of about 2.2 KV is applied between anode and cathode through current limiting resistors. A magnetic field is introduced at right angles to the plane of the electrodes by a permanent magnet which will increase the ionisation current. The electrons emitted from the cathode (gauge head body) of the gauge head are deflected by means of magnetic field applied at right angles to the plane of the electrodes and are made to take helical path before reaching the anode loop. Thus following very long path, the chance of collision with gas molecule is high even at low pressures. The secondary electrons produced by ionisation themselves perform similar oscillations and the rate of ionisation increases rapidly. Eventually, the electrons are captured by the anode and equilibrium is reached when the number of electrons produced per second by ionisation is the sum of positive ion current to the cathode and the electron current to the anode and is used to measure the pressure of the gas. This instrument with the sensor having wider range of applications, in high vacuum systems where the final Vacuum to be measured in process chamber.

Digital Pirani Gauge – Double Sensor – NST-D-2GH

The Vacuum Pirani Gauge Controller displays vacuum pressure as measured from a sensor tube. It displays vacuum measurements based on thermal conductivity of air or nitrogen. The Model DHPG controller covers the range from 0.001bar to 1000 mbar, and controls relay with independent set point.

Digital Pirani Gauge – Single Sensor – NST-D-1GH

The Vacuum Pirani Gauge Controller displays vacuum pressure as measured from a sensor tube. It displays vacuum measurements based on thermal conductivity of air or nitrogen. The Model DHPG controller covers the range from 0.001bar to 1000 mbar, and controls relay with independent set point.

Analogue Pirani Gauge – Double Sensor – NST-A-2GH

The Vacuum Pirani Gauge Controller displays vacuum pressure as measured from a sensor tube. It displays vacuum measurements based on thermal conductivity of air or nitrogen. The Model DHPG controller covers the range from 0.001bar to 1000 mbar, and controls relay with independent set point.

KF-40 BLANK FLANGE

KF VACUUM FITTINGS AND FLANGES

KF vacuum fittings and flanges consist of two flanges coupled together by a centering ring with a O-ring and a clamp. With this kind of connection provides many advantages, such as easy and quick mounting, assembly without any tools, unlimited orientation and easy interchangeability.

The standard sizes for KF vacuum fittings and flanges are KF-10, KF-16, KF-25, KF-40, and KF-50 with flange sizes NW-10, NW-16, NW-25, NW-40, and NW-50.

KF vacuum fittings and flanges are includes KF clamp, KF claw clamp, KF centering ring, KF o-ring, KF blank flange, KF bored weld flange, KF socket weld flange, KF half nipple, KF full nipple, KF reducing conical, KF elbows, KF tees, KF 4-way crosses, KF reducing tees, KF reducing 4-way crosses, KF flange to hose nozzle and so on.

KF-25 BLANK FLANGE

KF VACUUM FITTINGS AND FLANGES

KF vacuum fittings and flanges consist of two flanges coupled together by a centering ring with a O-ring and a clamp. With this kind of connection provides many advantages, such as easy and quick mounting, assembly without any tools, unlimited orientation and easy interchangeability.

The standard sizes for KF vacuum fittings and flanges are KF-10, KF-16, KF-25, KF-40, and KF-50 with flange sizes NW-10, NW-16, NW-25, NW-40, and NW-50.

KF vacuum fittings and flanges are includes KF clamp, KF claw clamp, KF centering ring, KF o-ring, KF blank flange, KF bored weld flange, KF socket weld flange, KF half nipple, KF full nipple, KF reducing conical, KF elbows, KF tees, KF 4-way crosses, KF reducing tees, KF reducing 4-way crosses, KF flange to hose nozzle and so on.

KF-16 BLANK FLANGE

KF VACUUM FITTINGS AND FLANGES

KF vacuum fittings and flanges consist of two flanges coupled together by a centering ring with a O-ring and a clamp. With this kind of connection provides many advantages, such as easy and quick mounting, assembly without any tools, unlimited orientation and easy interchangeability.

The standard sizes for KF vacuum fittings and flanges are KF-10, KF-16, KF-25, KF-40, and KF-50 with flange sizes NW-10, NW-16, NW-25, NW-40, and NW-50.

KF vacuum fittings and flanges are includes KF clamp, KF claw clamp, KF centering ring, KF o-ring, KF blank flange, KF bored weld flange, KF socket weld flange, KF half nipple, KF full nipple, KF reducing conical, KF elbows, KF tees, KF 4-way crosses, KF reducing tees, KF reducing 4-way crosses, KF flange to hose nozzle and so on.

KF-10 BLANK FLANGE

KF VACUUM FITTINGS AND FLANGES

KF vacuum fittings and flanges consist of two flanges coupled together by a centering ring with a O-ring and a clamp. With this kind of connection provides many advantages, such as easy and quick mounting, assembly without any tools, unlimited orientation and easy interchangeability.

The standard sizes for KF vacuum fittings and flanges are KF-10, KF-16, KF-25, KF-40, and KF-50 with flange sizes NW-10, NW-16, NW-25, NW-40, and NW-50.

KF vacuum fittings and flanges are includes KF clamp, KF claw clamp, KF centering ring, KF o-ring, KF blank flange, KF bored weld flange, KF socket weld flange, KF half nipple, KF full nipple, KF reducing conical, KF elbows, KF tees, KF 4-way crosses, KF reducing tees, KF reducing 4-way crosses, KF flange to hose nozzle and so on.

KF-40 CENTERING RING with NBR O-RING

KF VACUUM FITTINGS AND FLANGES

KF vacuum fittings and flanges consist of two flanges coupled together by a centering ring with a O-ring and a clamp. With this kind of connection provides many advantages, such as easy and quick mounting, assembly without any tools, unlimited orientation and easy interchangeability.

The standard sizes for KF vacuum fittings and flanges are KF-10, KF-16, KF-25, KF-40, and KF-50 with flange sizes NW-10, NW-16, NW-25, NW-40, and NW-50.

KF vacuum fittings and flanges are includes KF clamp, KF claw clamp, KF centering ring, KF o-ring, KF blank flange, KF bored weld flange, KF socket weld flange, KF half nipple, KF full nipple, KF reducing conical, KF elbows, KF tees, KF 4-way crosses, KF reducing tees, KF reducing 4-way crosses, KF flange to hose nozzle and so on.

KF-40 CENTERING RING with VITON O-RING

KF VACUUM FITTINGS AND FLANGES

KF vacuum fittings and flanges consist of two flanges coupled together by a centering ring with a O-ring and a clamp. With this kind of connection provides many advantages, such as easy and quick mounting, assembly without any tools, unlimited orientation and easy interchangeability.

The standard sizes for KF vacuum fittings and flanges are KF-10, KF-16, KF-25, KF-40, and KF-50 with flange sizes NW-10, NW-16, NW-25, NW-40, and NW-50.

KF vacuum fittings and flanges are includes KF clamp, KF claw clamp, KF centering ring, KF o-ring, KF blank flange, KF bored weld flange, KF socket weld flange, KF half nipple, KF full nipple, KF reducing conical, KF elbows, KF tees, KF 4-way crosses, KF reducing tees, KF reducing 4-way crosses, KF flange to hose nozzle and so on.

Popular Categories this Week

-

Plasma sputtering coater

‘NST’ Desktop plasma sputtering coater with rotary sample stage NST-PSC180G

This type of small plasma sputtering coating machine adopts two-stage sputtering method, which is widely used for SEM sample preparation or metal coating experiment. Using low-temperature plasma sputtering process, there is no high temperature during the coating process, and it is not easy to produce thermal damage.

SKU: n/a

Headphones

-

Plasma sputtering coater

‘NST’ Desktop plasma sputtering coater with rotary sample stage NST-PSC180G

This type of small plasma sputtering coating machine adopts two-stage sputtering method, which is widely used for SEM sample preparation or metal coating experiment. Using low-temperature plasma sputtering process, there is no high temperature during the coating process, and it is not easy to produce thermal damage.

SKU: n/a

Smartphones & Tablets

-

-

Muffle Furnaces (400 - 1900 C)

Vacuum arc Melting Furnace NST-AM180-V7X

This product is a small vacuum arc melting furnace with tungsten electrodes and water-cooled copper crucible. The equipment melting temperature can exceed 3000℃, and the temperature is reduced rapidly. The equipment adopts stainless steel water-cooled chamber and is equipped with a quartz observation window

SKU: n/a -

Atmosphere Furnace

Small vacuum induction furnace NST-IM315-S

This product is a small vacuum induction furnace with induction heating, and the melting temperature of the equipment can reach 2000℃. The induction furnace adopts a stainless steel water-cooled chamber and is equipped with a quartz observation window to observe the sample melting condition.

SKU: n/a

Recommendation For You

View All Recommendations-

Plasma sputtering coater

‘NST’ Desktop plasma sputtering coater with rotary sample stage NST-PSC180G

This type of small plasma sputtering coating machine adopts two-stage sputtering method, which is widely used for SEM sample preparation or metal coating experiment. Using low-temperature plasma sputtering process, there is no high temperature during the coating process, and it is not easy to produce thermal damage.

SKU: n/a -

Vacuum Measuring Instrument

Analogue Penning Gauge

Penning gauge is a cold cathode Ionisation gauge consisting of two electrodes anode and cathode in side sensor. A potential difference of about 2.2 KV is applied between anode and cathode through current limiting resistors. A magnetic field is introduced at right angles to the plane of the electrodes by a permanent magnet which will increase the ionisation current. The electrons emitted from the cathode (gauge head body) of the gauge head are deflected by means of magnetic field applied at right angles to the plane of the electrodes and are made to take helical path before reaching the anode loop. Thus following very long path, the chance of collision with gas molecule is high even at low pressures. The secondary electrons produced by ionisation themselves perform similar oscillations and the rate of ionisation increases rapidly. Eventually, the electrons are captured by the anode and equilibrium is reached when the number of electrons produced per second by ionisation is the sum of positive ion current to the cathode and the electron current to the anode and is used to measure the pressure of the gas. This instrument with the sensor having wider range of applications, in high vacuum systems where the final Vacuum to be measured in process chamber.

SKU: n/a -

Vacuum Measuring Instrument

Digital Penning Gauge

Penning gauge is a cold cathode Ionisation gauge consisting of two electrodes anode and cathode in side sensor. A potential difference of about 2.2 KV is applied between anode and cathode through current limiting resistors. A magnetic field is introduced at right angles to the plane of the electrodes by a permanent magnet which will increase the ionisation current. The electrons emitted from the cathode (gauge head body) of the gauge head are deflected by means of magnetic field applied at right angles to the plane of the electrodes and are made to take helical path before reaching the anode loop. Thus following very long path, the chance of collision with gas molecule is high even at low pressures. The secondary electrons produced by ionisation themselves perform similar oscillations and the rate of ionisation increases rapidly. Eventually, the electrons are captured by the anode and equilibrium is reached when the number of electrons produced per second by ionisation is the sum of positive ion current to the cathode and the electron current to the anode and is used to measure the pressure of the gas. This instrument with the sensor having wider range of applications, in high vacuum systems where the final Vacuum to be measured in process chamber.

SKU: n/a -

Vacuum Measuring Instrument

Digital Pirani Gauge – Double Sensor – NST-D-2GH

The Vacuum Pirani Gauge Controller displays vacuum pressure as measured from a sensor tube. It displays vacuum measurements based on thermal conductivity of air or nitrogen. The Model DHPG controller covers the range from 0.001bar to 1000 mbar, and controls relay with independent set point.

SKU: n/a