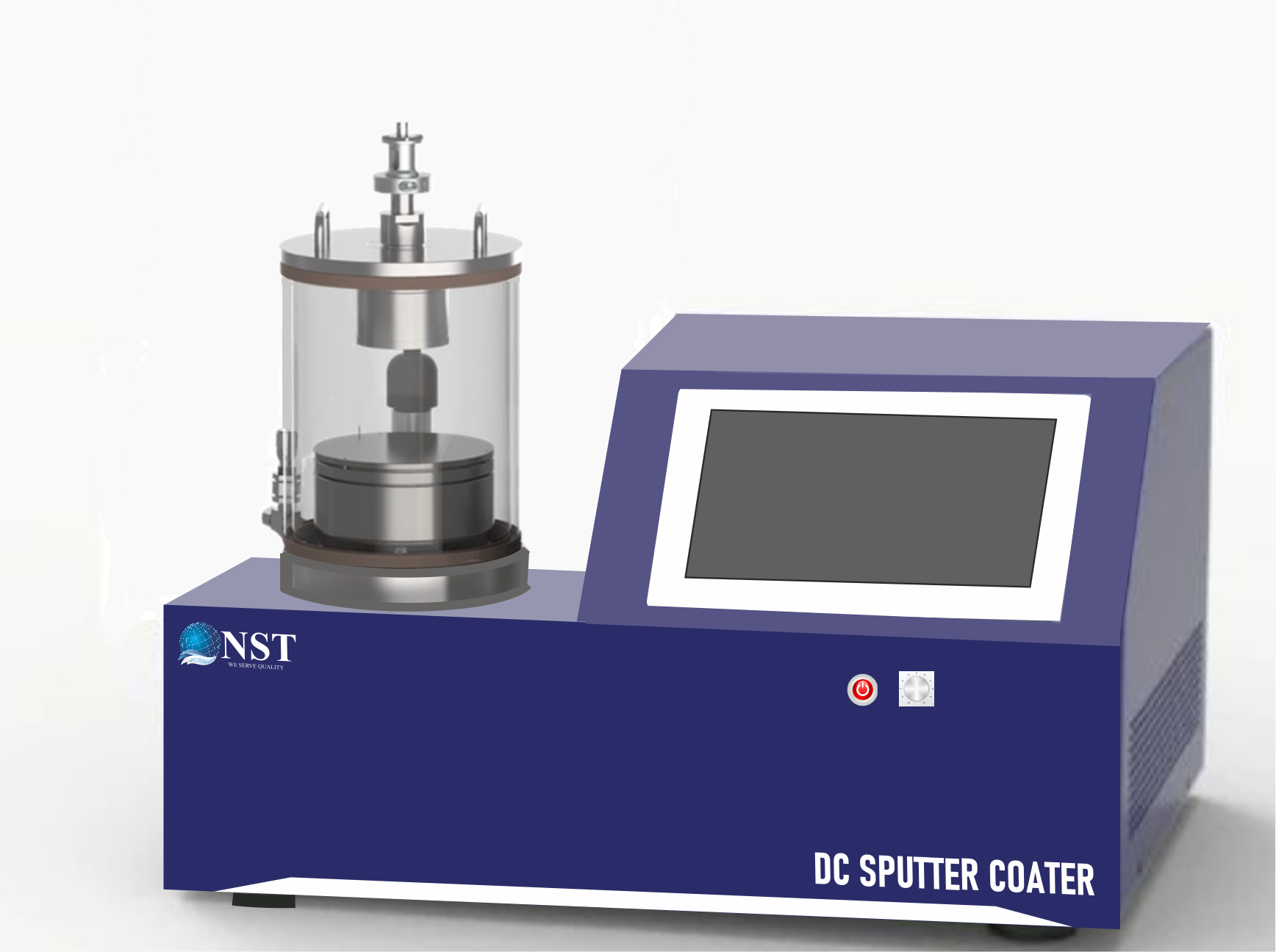

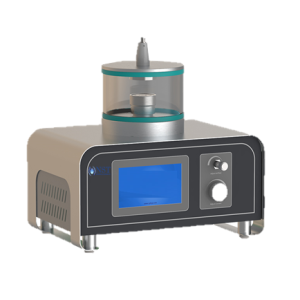

‘NST’ Desktop plasma sputtering coater with rotary sample stage NST-PSC180G

This type of small plasma sputtering coating machine adopts two-stage sputtering method, which is widely used for SEM sample preparation or metal coating experiment. Using low-temperature plasma sputtering process, there is no high temperature during the coating process, and it is not easy to produce thermal damage.

₹375,000.00 – ₹1,475,000.00

Compare-

Plasma sputtering coater

‘NST’ Desktop plasma sputtering coater with rotary sample stage NST-PSC180G

This type of small plasma sputtering coating machine adopts two-stage sputtering method, which is widely used for SEM sample preparation or metal coating experiment. Using low-temperature plasma sputtering process, there is no high temperature during the coating process, and it is not easy to produce thermal damage.

SKU: n/a -

Vacuum Fittings And Flanges

KF-25 CLAMP Aluminum

KF VACUUM FITTINGS AND FLANGES

KF vacuum fittings and flanges consist of two flanges coupled together by a centering ring with a O-ring and a clamp. With this kind of connection provides many advantages, such as easy and quick mounting, assembly without any tools, unlimited orientation and easy interchangeability.

The standard sizes for KF vacuum fittings and flanges are KF-10, KF-16, KF-25, KF-40, and KF-50 with flange sizes NW-10, NW-16, NW-25, NW-40, and NW-50.

KF vacuum fittings and flanges are includes KF clamp, KF claw clamp, KF centering ring, KF o-ring, KF blank flange, KF bored weld flange, KF socket weld flange, KF half nipple, KF full nipple, KF reducing conical, KF elbows, KF tees, KF 4-way crosses, KF reducing tees, KF reducing 4-way crosses, KF flange to hose nozzle and so on.

SKU: n/a

This type of small plasma sputtering coating machine adopts two-stage sputtering method, which is widely used for SEM sample preparation or metal coating experiment. Using low-temperature plasma sputtering process, there is no high temperature during the coating process, and it is not easy to produce thermal damage. This small plasma sputtering coater uses PLC control system, all touch screen operation, easy to learn and use. This model machine is also equipped with a rotatable sample stage, which can effectively improve the uniformity of the coating. This small plasma sputtering instrument uses a PLC control system, all touch screen operation, easy to learn and use. The equipment is small in size and beautiful in appearance, making it the best choice for laboratory coating experiments.

Technical parameters of plasma sputtering coater:

| Sample stage | Size | 135 mm |

| Rotating speed | 1~20rpm adjustable | |

| Plasma sputtering source | Quantity | 2 inchesx1 |

| Cooling method | Natural cooling | |

| Vacuum chamber | Chamber size | φ180mm x 210mm |

| Observation window | Omnidirectional visibility | |

| Chamber material | High purity quartz | |

| Open method | Top cover removable | |

| Upper and lower cover material | 304 stainless steel | |

| Pumping port | KF25 | |

| Intake port | 1/4 inch ferrule connector | |

| Power configuration | Quantity | DC power supplyx1 |

| Output power | Max. 150W | |

| Sputtering power | 1200V | |

| Max. sputtering current | 50mA | |

| Vacuum system | Vacuum pump type | Dual-stage rotary vane vacuum pump |

| Pumping port | KF25 | |

| Exhaust interface | KF25 | |

| Pumping rate | 250L/m(15m3/h) | |

| Ultimate vacuum | ≥0.1Pa | |

| Vacuum measurement | Resistance vacuum gauge | |

| Others | Power supply | AC 220V 50Hz |

| Total power | 1.5kW | |

| Dimension | 500mm x 320mm x470mm | |

| Weight | 30kg |

Disclaimer: The product introduction content (including product images, product descriptions, technical parameters, etc.) of this site is for reference only. As the update may not be timely, there will be some differences between the content and the actual situation. Please contact our sales staff to confirm. The information provided on this site does not constitute any offer or promise, and the company will periodically improve and modify the website information, without prior notice, please understand.

| Weight | 35 kg |

|---|---|

| Dimensions | N/A |

| Chamber Material | |

| Machine Operation | |

| Vacuum Pumping System | Diffusion Vacuum Pumping System, Rotary Vacuum Pump, Turbo Molecular Vacuum Pumping System |

There are no reviews yet.