Cutting / Dicing Saws

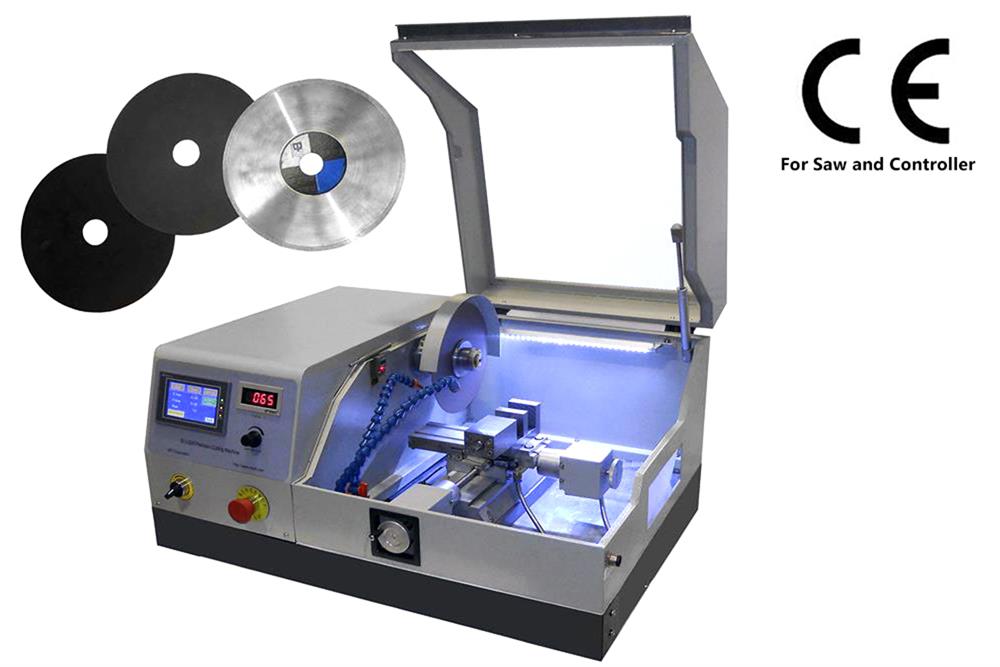

Automatic Section Saw ( 8″) with complete accessories NST-200

Availability:

Available on backorder

Compare

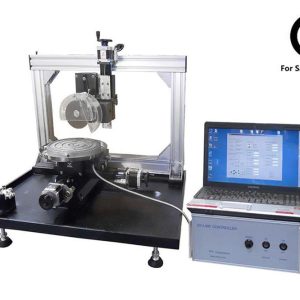

SYJ-200 is a CE certified automatic diamond saw for precisely cutting all type of materials. The saw is equipped with 8″ diameter diamond blade and touch-push panel to achieve automatic control. It is the perfect cutting tool for metallurgical, ceramic and materials research laboratories.

SPECIFICATIONS:

| Voltage and Power |

|

||||||

| Motor & Spindle |

|

||||||

| Sample Stage & Controller |

|

||||||

| Cutting Blade | Three 8″ cutting blades are included and completed accessories are included for immediate use

|

||||||

Water Cooling  |

|

||||||

| Dimensions | Overall dimensions: 734mm x540mm x475mm.   |

||||||

| Shipping Dimensions | 48″ x 40″ x 45″ | ||||||

| Shipping Weight | 365 lbs | ||||||

| Warranty & Compliance | Two (2) Years Limited Warranty with lifetime support (not include the rusty part due to improper storage) | ||||||

| Certification | CE certified. With additional certification fee, MTI can arrange NRTL to perform UL/CSA inspection and label the machine per customer’s request. | ||||||

| Application Note |

|

||||||

| Warning |

|

||||||

| Operation Instruction |  |

There are no reviews yet.