-

×

Dual-target NST magnetron sputtering coater (300W) NST-MSP300S-2RF

1 × ₹8,049,600.00

Dual-target NST magnetron sputtering coater (300W) NST-MSP300S-2RF

1 × ₹8,049,600.00 -

×

NST-HFV-K Series Diffusion Pump Oil

1 × ₹12,500.00

NST-HFV-K Series Diffusion Pump Oil

1 × ₹12,500.00 -

×

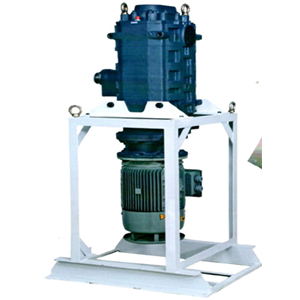

NST Multistage Chemical Dry Vacuum Pump

1 × ₹165,000.00

NST Multistage Chemical Dry Vacuum Pump

1 × ₹165,000.00 -

×

Dual-target RF magnetron sputtering coater NST-MSP300S-2RF-2FG

1 × ₹8,049,000.00

Dual-target RF magnetron sputtering coater NST-MSP300S-2RF-2FG

1 × ₹8,049,000.00 -

×

NST Laboratory 1100C Electric Muffle Furnace (4x4x4,1.0L)

1 × ₹350,000.00

NST Laboratory 1100C Electric Muffle Furnace (4x4x4,1.0L)

1 × ₹350,000.00 -

×

NST 1700°C Max Controlled Atmosphere Muffle Furnace W/ PC Interface

1 × ₹465,000.00

NST 1700°C Max Controlled Atmosphere Muffle Furnace W/ PC Interface

1 × ₹465,000.00 -

×

NST High Temperature Up To 1600C Microwave Muffle Furnace

1 × ₹1,290,000.00

NST High Temperature Up To 1600C Microwave Muffle Furnace

1 × ₹1,290,000.00 -

×

NST-300-1HD single target magnetron sputtering coater

1 × ₹4,024,800.00

NST-300-1HD single target magnetron sputtering coater

1 × ₹4,024,800.00

Subtotal: ₹22,405,900.00

There are no reviews yet.