Accessories Jumbotron

Recommended Products

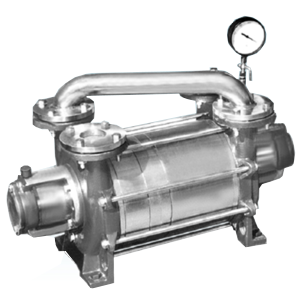

NST Two Stage Water Ring Vacuum Pump

NST has developed its series of Two Stage Liquid Ring Vacuum Pump based on positive displacement liquid ring principle which has a superior performance by getting higher vacuum and at comparatively low water consumption. it develops an ultimate vacuum of 720 mm hg at the sealing water temperature of 30°c with the capacity range of 30 to 1000 m3/hr., the same can be increased put 735 mm hg. When supplied with 15℃ to 18℃. this design is latest considering the saving of energy.

NST-10L 13.56MHz Plasma Cleaner

Featrues

1. Environmental technologies: plasma process is the role of gas – solid coherent reactor consumes no water resources, no need to add chemicals and no environmental pollution.

2. Wide adaptability: regardless of processing substrate type, such as metals, semiconductors.

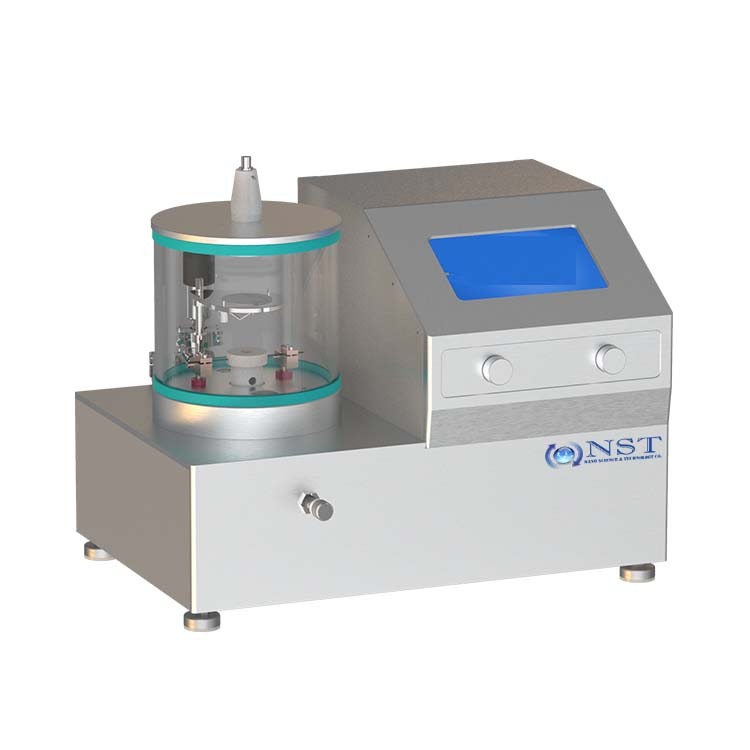

Dual-Target Magnetron Sputtering Coater NST-MSP300S-RFDC

Dual-target magnetron sputtering coater is a cost-effective magnetron sputtering coating equipment independently developed by our company. It is standardized, modular and customizable. There are 1-inch or 2-inch magnetron targets for you to choose. Customers can choose the target according to the size of the substrate to be coated

Small two-in-one coating machine NST-EVS180G-LV

Small two-in-one coating machine NST-EVS180G-LV

The small plasma sputtering and evaporation two-in-one coating machine is equipped with DC sputtering target and thermal evaporation assembly, which can not only be used for metal film plating by plasma sputtering, but also obtain carbon or other metal elemental films by evaporation.

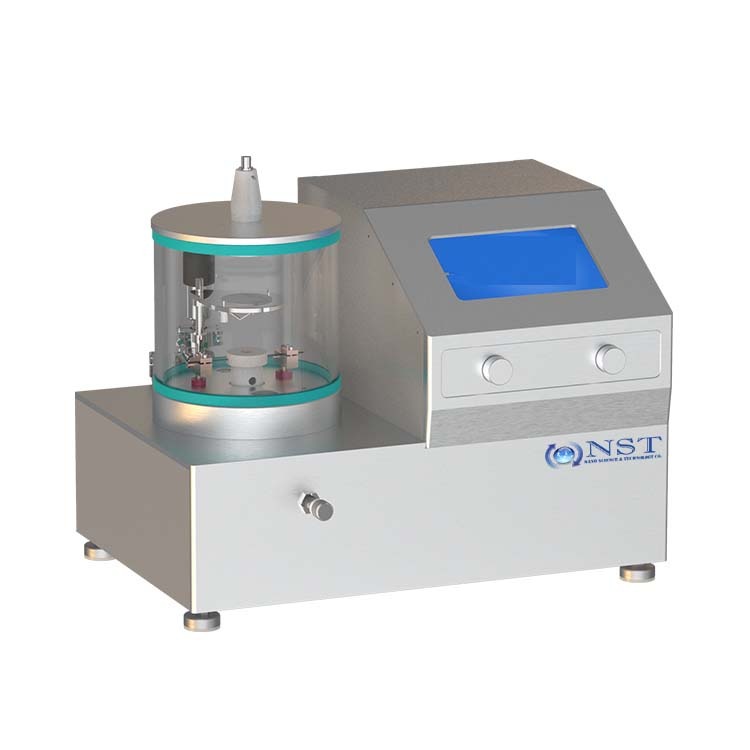

Three Target Heads Plasma Sputtering Coater NST-PSP180G-3TA

Three target heads plasma sputtering coater is a cost-effective plasma sputter coating equipment independently developed by our company. It has the advantages of compact structure, easy to use, high integration and strong sense of design

Small Plasma Sputtering Coater NST-PSP180G-1TA

Small plasma sputtering coater is a cost-effective plasma sputter coating equipment independently developed by our company. It has the advantages of compact structure, easy to use, high integration and strong sense of design.

Dual-Target Magnetron Sputtering Coater

Dual-target magnetron sputtering coater is a cost-effective magnetron sputtering coating equipment independently developed by our company. It is standardized, modular and customizable. There are 1-inch or 2-inch magnetron targets for you to choose. Customers can choose the target according to the size of the substrate to be coated

1000W 5L Plasma Cleaner NST-P5L-1000W

5L plasma cleaner is a compact, non-destructive cleaning device. The plasma cleaner uses low air pressure to excite plasma as a cleaning medium, thereby effectively avoiding secondary pollution caused by the liquid cleaning medium to the object to be cleaned

100W/150W 10L Plasma Cleaner NST-P10L-100W

10L plasma cleaner is a compact, non-destructive cleaning device. The plasma cleaner uses low air pressure to excite plasma as a cleaning medium, thereby effectively avoiding secondary pollution caused by the liquid cleaning medium to the object to be cleaned

300W / 500W 10L Oxygen Plasma Cleaner NST-P10L-300W/500W

10L plasma cleaner is a compact, non-destructive cleaning device. The plasma cleaner uses low air pressure to excite plasma as a cleaning medium, thereby effectively avoiding secondary pollution caused by the liquid cleaning medium to the object to be cleaned

1000W 10L Plasma Pleaner NST-P10L-1000W

10L plasma cleaner is a compact, non-destructive cleaning device. The plasma cleaner uses low air pressure to excite plasma as a cleaning medium, thereby effectively avoiding secondary pollution caused by the liquid cleaning medium to the object to be cleaned.

300W/500W 5L Oxygen Plasma Cleaner NST-P5L-300W

5L plasma cleaner is a compact, non-destructive cleaning device. The plasma cleaner uses low air pressure to excite plasma as a cleaning medium, thereby effectively avoiding secondary pollution caused by the liquid cleaning medium to the object to be cleaned