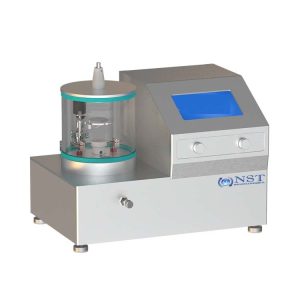

Automatic Powder Lithium Ion Battery Coating Machine

- Model Number:NST-DYG-135

- Input Power:55KW

- Dimension(L*W*H):1650*1400*2200mm

- Compliance:CE Certified

- Warranty:1 year

- Payment:L/C D/A D/P T/T Western Union

- Delivery Time:30 day

₹1.00

CompareAutomatic Powder Lithium ion Battery Coating Machine

Specifications:

The lithium battery coating machine TMAX-DYG-135 model coating machine is mainly used for Slurry drying process of lithium battery electrode coating. The battery coating machine adopts continuous coating mode, is mainly used for lithium battery lab research and pilot scale production line.

The process can be used to replace the original hand-scraping pulp, oven drying operation, and improve the uniformity of the squeegee and drying efficiency, is an indispensable equipment in mass production.

|

Model |

TMAX-DYG-135 |

|

Source voltage |

220V/ 380V, 50/60HZ |

|

Power |

6500W |

|

Warranty |

One Year limited warranty with lifetime support |

|

Max electrode width |

280mm |

|

Coating speed |

1m/min, adjustable |

|

Coating accuracy |

≤±0.003mm |

|

Roller diameter |

Φ100mm |

|

Max coating roller diameter |

Φ250mm |

|

Control pressure |

5-50N, adjustable |

|

Dry temperature |

RT-150℃, adjustable |

|

Oven length |

1.2m |

|

Air compression |

0.5-0.7MPa |

|

Coating mode |

Single face continuous coating |

|

Application foil |

Aluminum foil, Copper foil |

|

Weight |

About 1050kg |

|

Dimension(L*W*H) |

1800*810*1300mm |

|

Advantage |

1 Scraping system, parts processing precision, slurry contact part stainless steel structure, scraping thickness adjustable. 2 Main transmission adopts frequency control of motor speed, wide speed range speed constant and reliable for the speed control system, constant torque 3 Drying box adopts far infrared heating pipe, high heat efficiency, long service life 4 Using hot air circulation system, can make the temperature uniform, not easy to burn the pole piece 5 Temperature control adopts PID control system, high control accuracy, reliable work 6 The reeling adopts automatic correction system, pole piece coiling system |

There are no reviews yet.