-

×

NST 1400°C CVD Tube Furnace With Gas Mixing & Pumping System

1 × ₹1,236,852.00

NST 1400°C CVD Tube Furnace With Gas Mixing & Pumping System

1 × ₹1,236,852.00 -

×

Li Ion Battery Electrode Coating Machine For Laboratory

1 × ₹550,000.00

Li Ion Battery Electrode Coating Machine For Laboratory

1 × ₹550,000.00 -

×

Fiber Optic Y-shape Dual Light Microscope Illuminator - NST-Dual-Y-LD

1 × ₹49,252.00

Fiber Optic Y-shape Dual Light Microscope Illuminator - NST-Dual-Y-LD

1 × ₹49,252.00 -

×

Micrometer Adjustable Film Applicator - 150 Mm Width

1 × ₹25,500.00

Micrometer Adjustable Film Applicator - 150 Mm Width

1 × ₹25,500.00 -

×

Lithium Battery Slurry Electrode Coating Machine

1 × ₹550,000.00

Lithium Battery Slurry Electrode Coating Machine

1 × ₹550,000.00 -

×

filament for optical vacuum coater

1 × ₹2,900.00

filament for optical vacuum coater

1 × ₹2,900.00 -

×

Laboratory Small Battery Film Coater

1 × ₹650,000.00

Laboratory Small Battery Film Coater

1 × ₹650,000.00 -

×

NST-600-3HD three-target magnetron sputtering coater

1 × ₹7,585,200.00

NST-600-3HD three-target magnetron sputtering coater

1 × ₹7,585,200.00 -

×

NST-300-1HD single target magnetron sputtering coater

1 × ₹4,024,800.00

NST-300-1HD single target magnetron sputtering coater

1 × ₹4,024,800.00 -

×

High Quality Double Blade Micrometer Film Applicator

1 × ₹24,500.00

High Quality Double Blade Micrometer Film Applicator

1 × ₹24,500.00 -

×

Digital Low Speed Diamond Saw with Three 4" Cutting Blades & Complete Accessories - NST-150

1 × ₹618,890.00

Digital Low Speed Diamond Saw with Three 4" Cutting Blades & Complete Accessories - NST-150

1 × ₹618,890.00 -

×

10" Dia x 0.075" t x1.25" arbor SiC Abrasive Cutting Blades For Cut-off Saw- ST-SC1075

1 × ₹6,187.50

10" Dia x 0.075" t x1.25" arbor SiC Abrasive Cutting Blades For Cut-off Saw- ST-SC1075

1 × ₹6,187.50 -

×

NST-2-Zone 1600°C Tube Furnace With Vacuum Flanges & Alumina Tube

1 × ₹750,000.00

NST-2-Zone 1600°C Tube Furnace With Vacuum Flanges & Alumina Tube

1 × ₹750,000.00 -

×

NST Vacuum Carbon Tube Furnace

2 × ₹1,500,000.00

NST Vacuum Carbon Tube Furnace

2 × ₹1,500,000.00 -

×

NST High Purity Aluminum Filament

1 × ₹10,500.00

NST High Purity Aluminum Filament

1 × ₹10,500.00 -

×

Three targets NST magnetron sputtering coater NST-MSP300S-3NST

1 × ₹8,668,000.00

Three targets NST magnetron sputtering coater NST-MSP300S-3NST

1 × ₹8,668,000.00 -

×

NST-70mm rotary spray gun plasma cleaner

1 × ₹650,000.00

NST-70mm rotary spray gun plasma cleaner

1 × ₹650,000.00 -

×

NST-Atmospheric low temperature plasma cleaner

1 × ₹250,000.00

NST-Atmospheric low temperature plasma cleaner

1 × ₹250,000.00 -

×

NST Small high vacuum thermal evaporation coater

1 × ₹1,100,000.00

NST Small high vacuum thermal evaporation coater

1 × ₹1,100,000.00 -

×

NST-300-2HD dual target magnetron sputtering coater

1 × ₹4,024,800.00

NST-300-2HD dual target magnetron sputtering coater

1 × ₹4,024,800.00 -

×

Dual-Target Magnetron Sputtering Coater

2 × ₹8,100,000.00

Dual-Target Magnetron Sputtering Coater

2 × ₹8,100,000.00 -

×

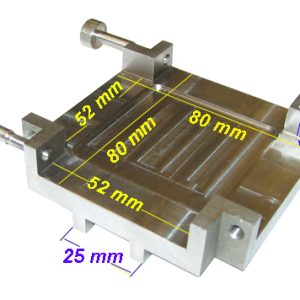

precision Cross Mount Vise for SXJ-2 Diamond Wire Saw

1 × ₹44,550.00

precision Cross Mount Vise for SXJ-2 Diamond Wire Saw

1 × ₹44,550.00 -

×

lubeCool -150 Smart Solid Lubricant and Coolant for Diamond Saw Cutting

1 × ₹1,450.00

lubeCool -150 Smart Solid Lubricant and Coolant for Diamond Saw Cutting

1 × ₹1,450.00 -

×

NST-Three-Zone 1200°C Tube Furnaces W/ Kanthal (Sweden) Heating Elements

1 × ₹750,000.00

NST-Three-Zone 1200°C Tube Furnaces W/ Kanthal (Sweden) Heating Elements

1 × ₹750,000.00 -

×

NST Vacuum Suspension Melting Furnace (0.3-2KG)

1 × ₹1,030,000.00

NST Vacuum Suspension Melting Furnace (0.3-2KG)

1 × ₹1,030,000.00 -

×

NST 3 Temperature Zone Sliding PECVD Tube Furnace

1 × ₹2,167,200.00

NST 3 Temperature Zone Sliding PECVD Tube Furnace

1 × ₹2,167,200.00

Subtotal: ₹53,970,581.50

There are no reviews yet.