-

×

NST Compact 4" RTP Tube Furnace System

1 × ₹913,320.00

NST Compact 4" RTP Tube Furnace System

1 × ₹913,320.00 -

×

NST Single-Zone 1200°C Vertical Tube Furnace

1 × ₹350,000.00

NST Single-Zone 1200°C Vertical Tube Furnace

1 × ₹350,000.00 -

×

NST-1400C Split Tube Furnace With Optional 1.6 - 4" Tube & 10" Long Heating Zone

1 × ₹750,000.00

NST-1400C Split Tube Furnace With Optional 1.6 - 4" Tube & 10" Long Heating Zone

1 × ₹750,000.00 -

×

NST 1200-1200C Double-Temperature Zone Rotatable Tube Furnace

1 × ₹1,070,000.00

NST 1200-1200C Double-Temperature Zone Rotatable Tube Furnace

1 × ₹1,070,000.00 -

×

NST-150 Vacuum Pump Red Copper Spring Parts

1 × ₹2,500.00

NST-150 Vacuum Pump Red Copper Spring Parts

1 × ₹2,500.00 -

×

NST High Purity Aluminum Ring

1 × ₹11,000.00

NST High Purity Aluminum Ring

1 × ₹11,000.00 -

×

NST High Purity Aluminum Filament

1 × ₹10,500.00

NST High Purity Aluminum Filament

1 × ₹10,500.00 -

×

NST 1700°C Atmosphere Muffle Furnace

1 × ₹450,000.00

NST 1700°C Atmosphere Muffle Furnace

1 × ₹450,000.00 -

×

High Speed Diamond Cut-off Saw with Vise and 5 pcs 4" Diamond Blades - NST-40-LD

1 × ₹117,000.00

High Speed Diamond Cut-off Saw with Vise and 5 pcs 4" Diamond Blades - NST-40-LD

1 × ₹117,000.00 -

×

NST-10L 13.56MHz Plasma Cleaner

1 × ₹840,000.00

NST-10L 13.56MHz Plasma Cleaner

1 × ₹840,000.00 -

×

NST 1200°C Muffle Furnace W/ Kanthal (Sweden) Heating Elements

1 × ₹550,000.00

NST 1200°C Muffle Furnace W/ Kanthal (Sweden) Heating Elements

1 × ₹550,000.00 -

×

NST-Compact UV-Ozone Cleaner

1 × ₹200,000.00

NST-Compact UV-Ozone Cleaner

1 × ₹200,000.00 -

×

NST Single Stage Oil Lubricate Vacuum Pump

1 × ₹35,000.00

NST Single Stage Oil Lubricate Vacuum Pump

1 × ₹35,000.00 -

×

NST 1700°C 40-Segment Muffle Furnace W/ PC Interface

1 × ₹550,000.00

NST 1700°C 40-Segment Muffle Furnace W/ PC Interface

1 × ₹550,000.00 -

×

NST Monoblock Rotary-Vane Vacuum Pump

1 × ₹78,000.00

NST Monoblock Rotary-Vane Vacuum Pump

1 × ₹78,000.00 -

×

1000W 10L Plasma Pleaner NST-P10L-1000W

1 × ₹1,150,000.00

1000W 10L Plasma Pleaner NST-P10L-1000W

1 × ₹1,150,000.00 -

×

NST Digital & Analogue Penning Gauge

1 × ₹9,500.00

NST Digital & Analogue Penning Gauge

1 × ₹9,500.00 -

×

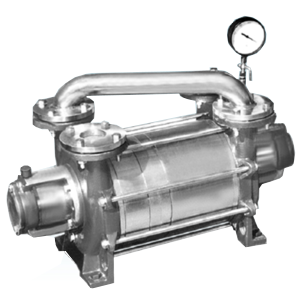

NST Two Stage Water Ring Vacuum Pump

1 × ₹65,000.00

NST Two Stage Water Ring Vacuum Pump

1 × ₹65,000.00 -

×

Through-Microscope Viewing for NST-202 Precision Diamond Wire Saw

1 × ₹241,315.00

Through-Microscope Viewing for NST-202 Precision Diamond Wire Saw

1 × ₹241,315.00 -

×

Ultra high pressure cold isostatic press NST-500CIP-30MAF

1 × ₹850,000.00

Ultra high pressure cold isostatic press NST-500CIP-30MAF

1 × ₹850,000.00

Subtotal: ₹8,243,135.00

There are no reviews yet.