Product Carousel Tabs

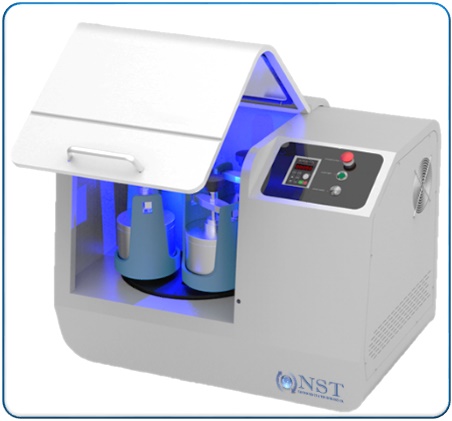

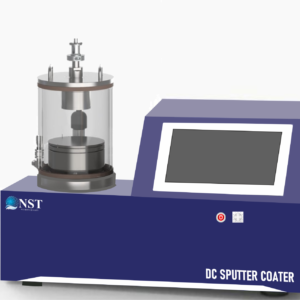

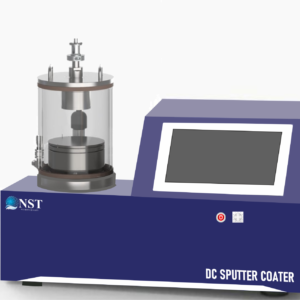

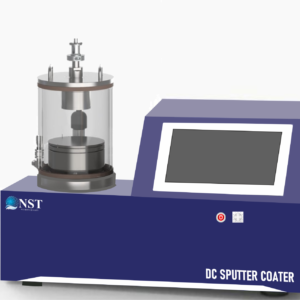

‘NST’ Desktop plasma sputtering coater with rotary sample stage NST-PSC180G

This type of small plasma sputtering coating machine adopts two-stage sputtering method, which is widely used for SEM sample preparation or metal coating experiment. Using low-temperature plasma sputtering process, there is no high temperature during the coating process, and it is not easy to produce thermal damage.

Analogue Penning Gauge

Penning gauge is a cold cathode Ionisation gauge consisting of two electrodes anode and cathode in side sensor. A potential difference of about 2.2 KV is applied between anode and cathode through current limiting resistors. A magnetic field is introduced at right angles to the plane of the electrodes by a permanent magnet which will increase the ionisation current. The electrons emitted from the cathode (gauge head body) of the gauge head are deflected by means of magnetic field applied at right angles to the plane of the electrodes and are made to take helical path before reaching the anode loop. Thus following very long path, the chance of collision with gas molecule is high even at low pressures. The secondary electrons produced by ionisation themselves perform similar oscillations and the rate of ionisation increases rapidly. Eventually, the electrons are captured by the anode and equilibrium is reached when the number of electrons produced per second by ionisation is the sum of positive ion current to the cathode and the electron current to the anode and is used to measure the pressure of the gas. This instrument with the sensor having wider range of applications, in high vacuum systems where the final Vacuum to be measured in process chamber.

Digital Penning Gauge

Penning gauge is a cold cathode Ionisation gauge consisting of two electrodes anode and cathode in side sensor. A potential difference of about 2.2 KV is applied between anode and cathode through current limiting resistors. A magnetic field is introduced at right angles to the plane of the electrodes by a permanent magnet which will increase the ionisation current. The electrons emitted from the cathode (gauge head body) of the gauge head are deflected by means of magnetic field applied at right angles to the plane of the electrodes and are made to take helical path before reaching the anode loop. Thus following very long path, the chance of collision with gas molecule is high even at low pressures. The secondary electrons produced by ionisation themselves perform similar oscillations and the rate of ionisation increases rapidly. Eventually, the electrons are captured by the anode and equilibrium is reached when the number of electrons produced per second by ionisation is the sum of positive ion current to the cathode and the electron current to the anode and is used to measure the pressure of the gas. This instrument with the sensor having wider range of applications, in high vacuum systems where the final Vacuum to be measured in process chamber.

Digital Pirani Gauge – Double Sensor – NST-D-2GH

The Vacuum Pirani Gauge Controller displays vacuum pressure as measured from a sensor tube. It displays vacuum measurements based on thermal conductivity of air or nitrogen. The Model DHPG controller covers the range from 0.001bar to 1000 mbar, and controls relay with independent set point.

Digital Pirani Gauge – Single Sensor – NST-D-1GH

The Vacuum Pirani Gauge Controller displays vacuum pressure as measured from a sensor tube. It displays vacuum measurements based on thermal conductivity of air or nitrogen. The Model DHPG controller covers the range from 0.001bar to 1000 mbar, and controls relay with independent set point.

Analogue Pirani Gauge – Double Sensor – NST-A-2GH

The Vacuum Pirani Gauge Controller displays vacuum pressure as measured from a sensor tube. It displays vacuum measurements based on thermal conductivity of air or nitrogen. The Model DHPG controller covers the range from 0.001bar to 1000 mbar, and controls relay with independent set point.

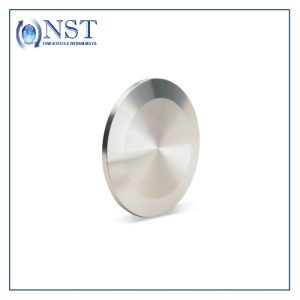

KF-40 BLANK FLANGE

KF VACUUM FITTINGS AND FLANGES

KF vacuum fittings and flanges consist of two flanges coupled together by a centering ring with a O-ring and a clamp. With this kind of connection provides many advantages, such as easy and quick mounting, assembly without any tools, unlimited orientation and easy interchangeability.

The standard sizes for KF vacuum fittings and flanges are KF-10, KF-16, KF-25, KF-40, and KF-50 with flange sizes NW-10, NW-16, NW-25, NW-40, and NW-50.

KF vacuum fittings and flanges are includes KF clamp, KF claw clamp, KF centering ring, KF o-ring, KF blank flange, KF bored weld flange, KF socket weld flange, KF half nipple, KF full nipple, KF reducing conical, KF elbows, KF tees, KF 4-way crosses, KF reducing tees, KF reducing 4-way crosses, KF flange to hose nozzle and so on.

KF-25 BLANK FLANGE

KF VACUUM FITTINGS AND FLANGES

KF vacuum fittings and flanges consist of two flanges coupled together by a centering ring with a O-ring and a clamp. With this kind of connection provides many advantages, such as easy and quick mounting, assembly without any tools, unlimited orientation and easy interchangeability.

The standard sizes for KF vacuum fittings and flanges are KF-10, KF-16, KF-25, KF-40, and KF-50 with flange sizes NW-10, NW-16, NW-25, NW-40, and NW-50.

KF vacuum fittings and flanges are includes KF clamp, KF claw clamp, KF centering ring, KF o-ring, KF blank flange, KF bored weld flange, KF socket weld flange, KF half nipple, KF full nipple, KF reducing conical, KF elbows, KF tees, KF 4-way crosses, KF reducing tees, KF reducing 4-way crosses, KF flange to hose nozzle and so on.

KF-16 BLANK FLANGE

KF VACUUM FITTINGS AND FLANGES

KF vacuum fittings and flanges consist of two flanges coupled together by a centering ring with a O-ring and a clamp. With this kind of connection provides many advantages, such as easy and quick mounting, assembly without any tools, unlimited orientation and easy interchangeability.

The standard sizes for KF vacuum fittings and flanges are KF-10, KF-16, KF-25, KF-40, and KF-50 with flange sizes NW-10, NW-16, NW-25, NW-40, and NW-50.

KF vacuum fittings and flanges are includes KF clamp, KF claw clamp, KF centering ring, KF o-ring, KF blank flange, KF bored weld flange, KF socket weld flange, KF half nipple, KF full nipple, KF reducing conical, KF elbows, KF tees, KF 4-way crosses, KF reducing tees, KF reducing 4-way crosses, KF flange to hose nozzle and so on.

KF-10 BLANK FLANGE

KF VACUUM FITTINGS AND FLANGES

KF vacuum fittings and flanges consist of two flanges coupled together by a centering ring with a O-ring and a clamp. With this kind of connection provides many advantages, such as easy and quick mounting, assembly without any tools, unlimited orientation and easy interchangeability.

The standard sizes for KF vacuum fittings and flanges are KF-10, KF-16, KF-25, KF-40, and KF-50 with flange sizes NW-10, NW-16, NW-25, NW-40, and NW-50.

KF vacuum fittings and flanges are includes KF clamp, KF claw clamp, KF centering ring, KF o-ring, KF blank flange, KF bored weld flange, KF socket weld flange, KF half nipple, KF full nipple, KF reducing conical, KF elbows, KF tees, KF 4-way crosses, KF reducing tees, KF reducing 4-way crosses, KF flange to hose nozzle and so on.

KF-40 CENTERING RING with NBR O-RING

KF VACUUM FITTINGS AND FLANGES

KF vacuum fittings and flanges consist of two flanges coupled together by a centering ring with a O-ring and a clamp. With this kind of connection provides many advantages, such as easy and quick mounting, assembly without any tools, unlimited orientation and easy interchangeability.

The standard sizes for KF vacuum fittings and flanges are KF-10, KF-16, KF-25, KF-40, and KF-50 with flange sizes NW-10, NW-16, NW-25, NW-40, and NW-50.

KF vacuum fittings and flanges are includes KF clamp, KF claw clamp, KF centering ring, KF o-ring, KF blank flange, KF bored weld flange, KF socket weld flange, KF half nipple, KF full nipple, KF reducing conical, KF elbows, KF tees, KF 4-way crosses, KF reducing tees, KF reducing 4-way crosses, KF flange to hose nozzle and so on.

KF-40 CENTERING RING with VITON O-RING

KF VACUUM FITTINGS AND FLANGES

KF vacuum fittings and flanges consist of two flanges coupled together by a centering ring with a O-ring and a clamp. With this kind of connection provides many advantages, such as easy and quick mounting, assembly without any tools, unlimited orientation and easy interchangeability.

The standard sizes for KF vacuum fittings and flanges are KF-10, KF-16, KF-25, KF-40, and KF-50 with flange sizes NW-10, NW-16, NW-25, NW-40, and NW-50.

KF vacuum fittings and flanges are includes KF clamp, KF claw clamp, KF centering ring, KF o-ring, KF blank flange, KF bored weld flange, KF socket weld flange, KF half nipple, KF full nipple, KF reducing conical, KF elbows, KF tees, KF 4-way crosses, KF reducing tees, KF reducing 4-way crosses, KF flange to hose nozzle and so on.

‘NST’ Desktop plasma sputtering coater with rotary sample stage NST-PSC180G

This type of small plasma sputtering coating machine adopts two-stage sputtering method, which is widely used for SEM sample preparation or metal coating experiment. Using low-temperature plasma sputtering process, there is no high temperature during the coating process, and it is not easy to produce thermal damage.

1000W 10L Plasma Pleaner NST-P10L-1000W

10L plasma cleaner is a compact, non-destructive cleaning device. The plasma cleaner uses low air pressure to excite plasma as a cleaning medium, thereby effectively avoiding secondary pollution caused by the liquid cleaning medium to the object to be cleaned.

1000W 2L plasma cleaner NST-P2L-1000W

The plasma cleaner is a compact, non-destructive cleaning device. The plasma cleaner uses low air pressure to excite plasma as a cleaning medium, thereby effectively avoiding secondary pollution caused by the liquid cleaning medium to the object to be cleaned.

1000W 5L Plasma Cleaner NST-P5L-1000W

5L plasma cleaner is a compact, non-destructive cleaning device. The plasma cleaner uses low air pressure to excite plasma as a cleaning medium, thereby effectively avoiding secondary pollution caused by the liquid cleaning medium to the object to be cleaned

100W/150W 10L Plasma Cleaner NST-P10L-100W

10L plasma cleaner is a compact, non-destructive cleaning device. The plasma cleaner uses low air pressure to excite plasma as a cleaning medium, thereby effectively avoiding secondary pollution caused by the liquid cleaning medium to the object to be cleaned

100W/150W 2L plasma cleaner NST-P2L-100/150W

Plasma cleaning machine divided into two types, atmospheric and vacuum; it is widely used in semi-conductor, PCB, medical diagnosis, elastomer industry, optical industry,etc.

NST generator has 40KHz, 13.56Mhz, and 2.45GHz. According to the usage, can choose the suitable NST.

100W/150W 5L plasma cleaner NST-P5L-100W

100W/150W 5L plasma cleaner NST-P5L-100W

5L plasma cleaner is a compact, non-destructive cleaning device. The plasma cleaner uses low air pressure to excite plasma as a cleaning medium, thereby effectively avoiding secondary pollution caused by the liquid cleaning medium to the object to be cleaned.

300W / 500W 10L Oxygen Plasma Cleaner NST-P10L-300W/500W

10L plasma cleaner is a compact, non-destructive cleaning device. The plasma cleaner uses low air pressure to excite plasma as a cleaning medium, thereby effectively avoiding secondary pollution caused by the liquid cleaning medium to the object to be cleaned

300W/500W 2L plasma cleaning machine NST-P2L-500W

Plasma cleaner is a compact, non-destructive cleaning device. The plasma cleaner uses low air pressure to excite plasma as a cleaning medium, thereby effectively avoiding secondary pollution caused by the liquid cleaning medium to the object to be cleaned.

300W/500W 5L Oxygen Plasma Cleaner NST-P5L-300W

5L plasma cleaner is a compact, non-destructive cleaning device. The plasma cleaner uses low air pressure to excite plasma as a cleaning medium, thereby effectively avoiding secondary pollution caused by the liquid cleaning medium to the object to be cleaned

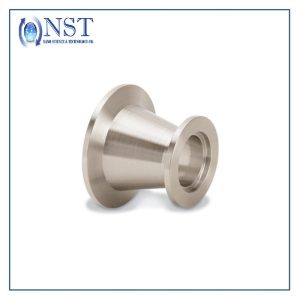

KF REDUCING CONICAL

KF VACUUM FITTINGS AND FLANGES

KF vacuum fittings and flanges consist of two flanges coupled together by a centering ring with a O-ring and a clamp. With this kind of connection provides many advantages, such as easy and quick mounting, assembly without any tools, unlimited orientation and easy interchangeability.

The standard sizes for KF vacuum fittings and flanges are KF-10, KF-16, KF-25, KF-40, and KF-50 with flange sizes NW-10, NW-16, NW-25, NW-40, and NW-50.

KF vacuum fittings and flanges are includes KF clamp, KF claw clamp, KF centering ring, KF o-ring, KF blank flange, KF bored weld flange, KF socket weld flange, KF half nipple, KF full nipple, KF reducing conical, KF elbows, KF tees, KF 4-way crosses, KF reducing tees, KF reducing 4-way crosses, KF flange to hose nozzle and so on.

Lab compact UV-ozone cleaner with 6″×6″ chamber

Lab compact UV-ozone cleaner is a compact Ultraviolet (UV) Ozone cleaner, which is a dedicated system to remove a variety of contaminants from surfaces of substrates samples. UV Ozone cleaning is a simple to use dry process which is highly effective method to clean surfaces.

NST board plasma cleaning machine

The NST board plasma cleaning machine can be processed online at high speed to improve production efficiency. The characteristics of the plasma are used to clean, activate and activate the surface of the solid material to be treated, thereby realizing the purpose of changing the surface microstructure, chemical properties and energy.

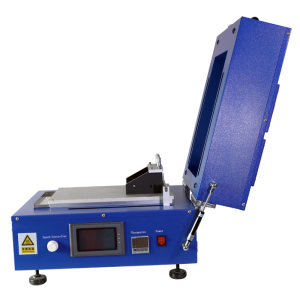

NST Compact Tape Casting Coater w/ Vacuum Chuck (8″Wx14″L), Film Applicator & Optional 200ºC Dryer Cover

NST Compact Tape Casting Coater w/ Vacuum Chuck (8″Wx14″L), Film Applicator & Optional 200ºC Dryer Cover

NST Oxygen Plasma Cleaner

Featrues

1. Environmental technologies: plasma process is the role of gas – solid coherent reactor consumes no water resources, no need to add chemicals and no environmental pollution.

2. Wide adaptability: regardless of processing substrate type, such as metals, semiconductors, oxides.

NST-10L 13.56MHz Plasma Cleaner

Featrues

1. Environmental technologies: plasma process is the role of gas – solid coherent reactor consumes no water resources, no need to add chemicals and no environmental pollution.

2. Wide adaptability: regardless of processing substrate type, such as metals, semiconductors.

NST-5L Plasma Cleaner

Featrues

1. Environmental technologies: plasma process is the role of gas – solid coherent reactor consumes no water resources, no need to add chemicals and no environmental pollution.

2. Wide adaptability: regardless of processing substrate type, such as metals, semiconductors, oxides, and most.

Dual-Target Magnetron Sputtering Coater NST-MSP300S-RFDC

Dual-target magnetron sputtering coater is a cost-effective magnetron sputtering coating equipment independently developed by our company. It is standardized, modular and customizable. There are 1-inch or 2-inch magnetron targets for you to choose. Customers can choose the target according to the size of the substrate to be coated

NST-4mm direct spray gun plasma cleaner

NST-4mm direct spray gun plasma cleaner can’t produce any pollution,when it is processing the machine,which can be matched with the original production line, to achieve fully automatic online production, saving labor costs, using plasma to achieve the results that conventional cleaning methods can not achieve.

NST-300-1HD single target magnetron sputtering coater

NST-300-1HD single target magnetron sputtering coater

Single target magnetron sputtering coater is equipped with a magnetron sputtering target with a water-cooled interlayer, a 140mm heatable rotating stage, and a DC power supply. The vacuum chamber adopts the top opening method, which makes it easier to change the target. It is an ideal device for making various metal films.

Beijing Sifang SK-3 Diffusion Pump Oil

Beijing Sifang SK-3 Diffusion Pump Oil

Sifang Brand diffusion pump oil adopt paraffinic mineral oil fractions as raw material, after deep purification of its components, then excised molecular distillation fraction and degassed in a high-vacuum , precise temperature control can effectively guarantee the cut fractions, ensure the diffusion pump can quickly vaporize and condense during working, resulting in high-speed jet stream, greatly improved the pumping speed and vacuum degree of the diffusion pump.

NST Roll To Roll Transfer Coating System ( Max. 300 Mm Width)

NST Roll To Roll Transfer Coating System ( Max. 300 Mm Width)

NST-MRX300

Max 300mm width

1000kg

CE Certified

Two years limited warranty with lifetime technical support

L/C D/A D/P T/T Western Union

10 day

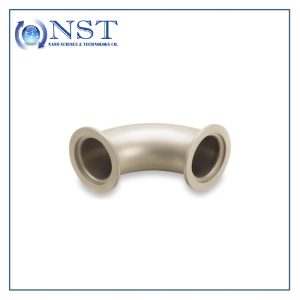

KF-40 ELBOW

KF VACUUM FITTINGS AND FLANGES

KF vacuum fittings and flanges consist of two flanges coupled together by a centering ring with a O-ring and a clamp. With this kind of connection provides many advantages, such as easy and quick mounting, assembly without any tools, unlimited orientation and easy interchangeability.

The standard sizes for KF vacuum fittings and flanges are KF-10, KF-16, KF-25, KF-40, and KF-50 with flange sizes NW-10, NW-16, NW-25, NW-40, and NW-50.

KF vacuum fittings and flanges are includes KF clamp, KF claw clamp, KF centering ring, KF o-ring, KF blank flange, KF bored weld flange, KF socket weld flange, KF half nipple, KF full nipple, KF reducing conical, KF elbows, KF tees, KF 4-way crosses, KF reducing tees, KF reducing 4-way crosses, KF flange to hose nozzle and so on.

NST Small high vacuum two-in-one film coater

NST Small high vacuum two-in-one film coater

The plasma sputtering and evaporating two-in-one film coater is equipped with DC sputtering target and thermal evaporation assembly, which can be used not only for plasma sputtering, but also obtain carbon or other metal simple films by evaporation.

NST-3 heads compact RF plasma magnetron sputtering coater

NST-3 heads compact RF plasma magnetron sputtering coater

NST 3 heads compact RF plasma magnetron sputtering coater is designed for non-metallic thin film coating, mainly for multilayer oxide thin films.DC magnetron sputtering option is available upon request for metallic film deposition, enabling three DC, one RF/two DC, and two RF/one DC sputtering head configurations.

Home Entertainment

-

Plasma sputtering coater

Plasma sputtering coater‘NST’ Desktop plasma sputtering coater with rotary sample stage NST-PSC180G

₹375,000.00 – ₹1,475,000.00

Laptops & Computers

-

Plasma sputtering coater

Plasma sputtering coater‘NST’ Desktop plasma sputtering coater with rotary sample stage NST-PSC180G

₹375,000.00 – ₹1,475,000.00

Trending Products

-

Plasma sputtering coater

Plasma sputtering coater‘NST’ Desktop plasma sputtering coater with rotary sample stage NST-PSC180G

₹375,000.00 – ₹1,475,000.00

Bestseller

Top Categories of this Month

Recommendation for you

‘NST’ Desktop plasma sputtering coater with rotary sample stage NST-PSC180G

This type of small plasma sputtering coating machine adopts two-stage sputtering method, which is widely used for SEM sample preparation or metal coating experiment. Using low-temperature plasma sputtering process, there is no high temperature during the coating process, and it is not easy to produce thermal damage.

Analogue Penning Gauge

Penning gauge is a cold cathode Ionisation gauge consisting of two electrodes anode and cathode in side sensor. A potential difference of about 2.2 KV is applied between anode and cathode through current limiting resistors. A magnetic field is introduced at right angles to the plane of the electrodes by a permanent magnet which will increase the ionisation current. The electrons emitted from the cathode (gauge head body) of the gauge head are deflected by means of magnetic field applied at right angles to the plane of the electrodes and are made to take helical path before reaching the anode loop. Thus following very long path, the chance of collision with gas molecule is high even at low pressures. The secondary electrons produced by ionisation themselves perform similar oscillations and the rate of ionisation increases rapidly. Eventually, the electrons are captured by the anode and equilibrium is reached when the number of electrons produced per second by ionisation is the sum of positive ion current to the cathode and the electron current to the anode and is used to measure the pressure of the gas. This instrument with the sensor having wider range of applications, in high vacuum systems where the final Vacuum to be measured in process chamber.

Digital Penning Gauge

Penning gauge is a cold cathode Ionisation gauge consisting of two electrodes anode and cathode in side sensor. A potential difference of about 2.2 KV is applied between anode and cathode through current limiting resistors. A magnetic field is introduced at right angles to the plane of the electrodes by a permanent magnet which will increase the ionisation current. The electrons emitted from the cathode (gauge head body) of the gauge head are deflected by means of magnetic field applied at right angles to the plane of the electrodes and are made to take helical path before reaching the anode loop. Thus following very long path, the chance of collision with gas molecule is high even at low pressures. The secondary electrons produced by ionisation themselves perform similar oscillations and the rate of ionisation increases rapidly. Eventually, the electrons are captured by the anode and equilibrium is reached when the number of electrons produced per second by ionisation is the sum of positive ion current to the cathode and the electron current to the anode and is used to measure the pressure of the gas. This instrument with the sensor having wider range of applications, in high vacuum systems where the final Vacuum to be measured in process chamber.

Digital Pirani Gauge – Double Sensor – NST-D-2GH

The Vacuum Pirani Gauge Controller displays vacuum pressure as measured from a sensor tube. It displays vacuum measurements based on thermal conductivity of air or nitrogen. The Model DHPG controller covers the range from 0.001bar to 1000 mbar, and controls relay with independent set point.