-

×

NST Two-Way Molybdenum Wire Vacuum Hot Pressing Furnace

1 × ₹8,839,080.00

NST Two-Way Molybdenum Wire Vacuum Hot Pressing Furnace

1 × ₹8,839,080.00 -

×

NST High Purity Aluminum Ring

1 × ₹11,000.00

NST High Purity Aluminum Ring

1 × ₹11,000.00 -

×

Titanium target

1 × ₹6,000.00

Titanium target

1 × ₹6,000.00 -

×

Three targets NST magnetron sputtering coater NST-MSP300S-3NST

1 × ₹8,668,000.00

Three targets NST magnetron sputtering coater NST-MSP300S-3NST

1 × ₹8,668,000.00 -

×

NST Organic and inorganic evaporation coater

1 × ₹10,400,000.00

NST Organic and inorganic evaporation coater

1 × ₹10,400,000.00 -

×

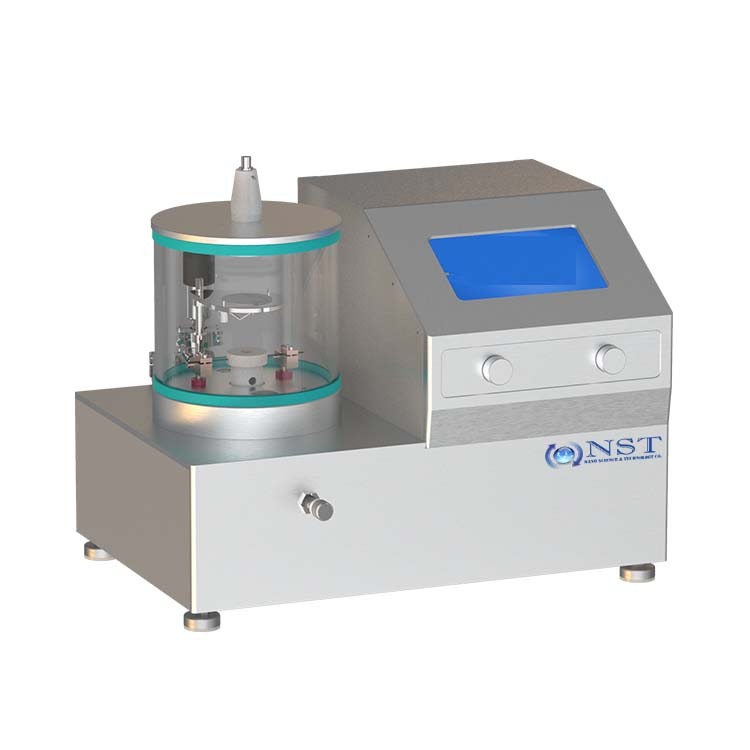

NST Small high vacuum thermal evaporation coater

1 × ₹1,100,000.00

NST Small high vacuum thermal evaporation coater

1 × ₹1,100,000.00 -

×

NST-300-2HD dual target magnetron sputtering coater

1 × ₹4,024,800.00

NST-300-2HD dual target magnetron sputtering coater

1 × ₹4,024,800.00 -

×

NST Roll To Roll Transfer Coating System ( Max. 300 Mm Width)

1 × ₹4,628,520.00

NST Roll To Roll Transfer Coating System ( Max. 300 Mm Width)

1 × ₹4,628,520.00 -

×

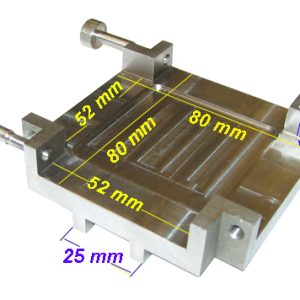

precision Cross Mount Vise for SXJ-2 Diamond Wire Saw

1 × ₹44,550.00

precision Cross Mount Vise for SXJ-2 Diamond Wire Saw

1 × ₹44,550.00 -

×

Three targets NST magnetron sputtering coater NST-MSP300S-3DC

1 × ₹8,668,000.00

Three targets NST magnetron sputtering coater NST-MSP300S-3DC

1 × ₹8,668,000.00 -

×

NST Roll To Roll Transfer Coating System

1 × ₹3,700,000.00

NST Roll To Roll Transfer Coating System

1 × ₹3,700,000.00 -

×

Three Target Heads Plasma Sputtering Coater NST-PSP180G-3TA

1 × ₹1,850,000.00

Three Target Heads Plasma Sputtering Coater NST-PSP180G-3TA

1 × ₹1,850,000.00 -

×

NST Small Roll To Roll Battery Electrode Continuous Coating Machine

1 × ₹928,800.00

NST Small Roll To Roll Battery Electrode Continuous Coating Machine

1 × ₹928,800.00 -

×

Three targets magnetron sputtering coater NST-MSP300S-2DC1RF

1 × ₹8,700,000.00

Three targets magnetron sputtering coater NST-MSP300S-2DC1RF

1 × ₹8,700,000.00

Subtotal: ₹61,568,750.00

There are no reviews yet.