-

×

NST Single-Zone 1200°C Vertical Tube Furnace

1 × ₹350,000.00

NST Single-Zone 1200°C Vertical Tube Furnace

1 × ₹350,000.00 -

×

NST Single-Zone 1200°C Split Tube Furnace

3 × ₹1,400,000.00

NST Single-Zone 1200°C Split Tube Furnace

3 × ₹1,400,000.00 -

×

NST High Temperture 1500C Two Zone Rotary Tube Furnace

1 × ₹1,100,000.00

NST High Temperture 1500C Two Zone Rotary Tube Furnace

1 × ₹1,100,000.00 -

×

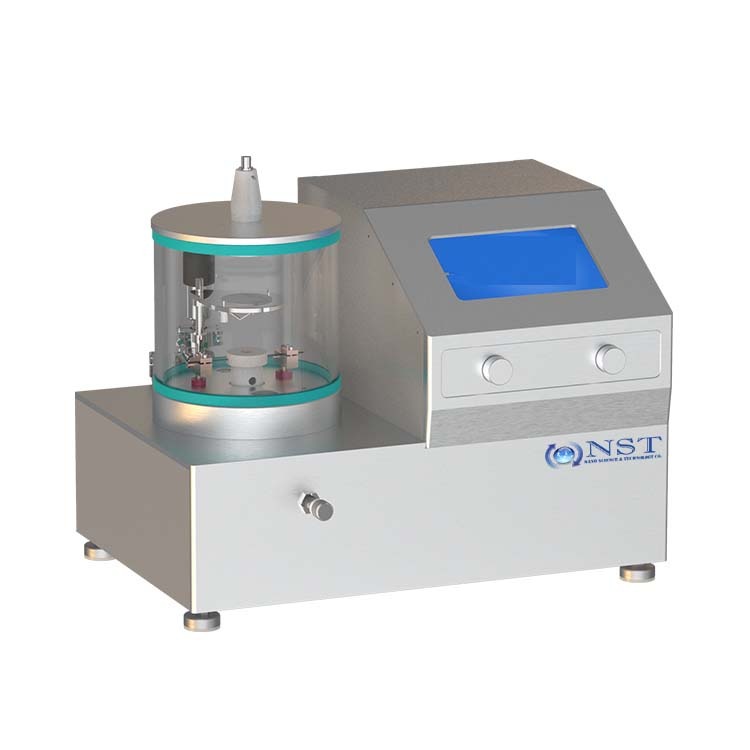

NST Small high vacuum thermal evaporation coater

1 × ₹1,100,000.00

NST Small high vacuum thermal evaporation coater

1 × ₹1,100,000.00 -

×

Dual-target RF magnetron sputtering coater NST-MSP300S-2RF-2FG

1 × ₹8,049,000.00

Dual-target RF magnetron sputtering coater NST-MSP300S-2RF-2FG

1 × ₹8,049,000.00 -

×

NST-Double-Zone 1200°C Tube Furnace W/ Kanthal (Sweden) Heating Elements

1 × ₹750,000.00

NST-Double-Zone 1200°C Tube Furnace W/ Kanthal (Sweden) Heating Elements

1 × ₹750,000.00 -

×

NST High Temperture 1200-1200-1200 Three-Temperature Zone Rotary Tube Furnace

2 × ₹1,090,000.00

NST High Temperture 1200-1200-1200 Three-Temperature Zone Rotary Tube Furnace

2 × ₹1,090,000.00 -

×

NST 1200°C Muffle Furnace W/ Kanthal (Sweden) Heating Elements

1 × ₹550,000.00

NST 1200°C Muffle Furnace W/ Kanthal (Sweden) Heating Elements

1 × ₹550,000.00 -

×

NST 3 Temperature Zone 150 Mm OD PECVD Furnace

1 × ₹2,167,200.00

NST 3 Temperature Zone 150 Mm OD PECVD Furnace

1 × ₹2,167,200.00 -

×

NST 1200°C Dual Zones CVD Tube Furnace

1 × ₹1,377,720.00

NST 1200°C Dual Zones CVD Tube Furnace

1 × ₹1,377,720.00 -

×

Three targets magnetron sputtering coater NST-MSP300S-2DC1RF

1 × ₹8,700,000.00

Three targets magnetron sputtering coater NST-MSP300S-2DC1RF

1 × ₹8,700,000.00 -

×

NST-300-2HD dual target magnetron sputtering coater

1 × ₹4,024,800.00

NST-300-2HD dual target magnetron sputtering coater

1 × ₹4,024,800.00 -

×

NST-300-1HD single target magnetron sputtering coater

1 × ₹4,024,800.00

NST-300-1HD single target magnetron sputtering coater

1 × ₹4,024,800.00 -

×

NST 3 Temperature Zone Sliding PECVD Tube Furnace

1 × ₹2,167,200.00

NST 3 Temperature Zone Sliding PECVD Tube Furnace

1 × ₹2,167,200.00 -

×

NST-Three-Zone 1200°C Tube Furnaces W/ Kanthal (Sweden) Heating Elements

1 × ₹750,000.00

NST-Three-Zone 1200°C Tube Furnaces W/ Kanthal (Sweden) Heating Elements

1 × ₹750,000.00 -

×

Small two-in-one coating machine NST-EVS180G-LV

1 × ₹650,000.00

Small two-in-one coating machine NST-EVS180G-LV

1 × ₹650,000.00 -

×

NST-1400C Split Tube Furnace With Optional 1.6 - 4" Tube & 10" Long Heating Zone

1 × ₹750,000.00

NST-1400C Split Tube Furnace With Optional 1.6 - 4" Tube & 10" Long Heating Zone

1 × ₹750,000.00 -

×

NST Single chamber magnetron sputtering system

1 × ₹2,350,000.00

NST Single chamber magnetron sputtering system

1 × ₹2,350,000.00 -

×

NST 1200°C Vertical PECVD Furnace With RF Generator, Gas Mix & Pumping System

1 × ₹950,000.00

NST 1200°C Vertical PECVD Furnace With RF Generator, Gas Mix & Pumping System

1 × ₹950,000.00 -

×

Ultra high pressure cold isostatic press NST-500CIP-30MAF

1 × ₹850,000.00

Ultra high pressure cold isostatic press NST-500CIP-30MAF

1 × ₹850,000.00

Subtotal: ₹47,040,720.00

There are no reviews yet.