-

×

NST-Three-Zone 1200°C Tube Furnaces W/ Kanthal (Sweden) Heating Elements

1 × ₹750,000.00

NST-Three-Zone 1200°C Tube Furnaces W/ Kanthal (Sweden) Heating Elements

1 × ₹750,000.00 -

×

NST Single-Zone 1800°C Max 80mm OD Tube Furnace

1 × ₹1,532,520.00

NST Single-Zone 1800°C Max 80mm OD Tube Furnace

1 × ₹1,532,520.00 -

×

NST-HFV-K Series Diffusion Pump Oil

1 × ₹12,500.00

NST-HFV-K Series Diffusion Pump Oil

1 × ₹12,500.00 -

×

NST Leod gauge

1 × ₹4,500.00

NST Leod gauge

1 × ₹4,500.00 -

×

NST-50L 200C Vacuum Dry Oven (16.3 X 13.5 X 14.5" ) With Digital Temperature Controller

1 × ₹450,000.00

NST-50L 200C Vacuum Dry Oven (16.3 X 13.5 X 14.5" ) With Digital Temperature Controller

1 × ₹450,000.00 -

×

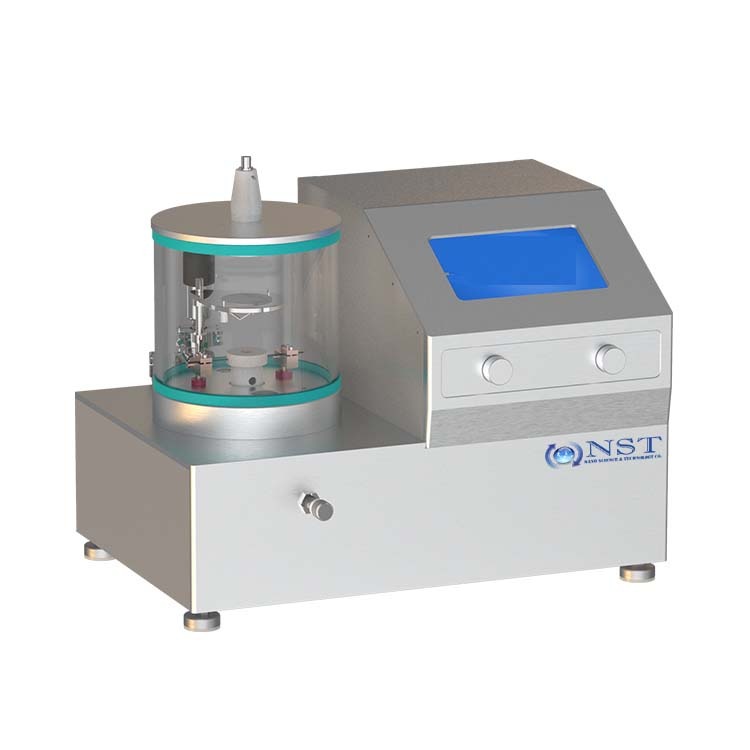

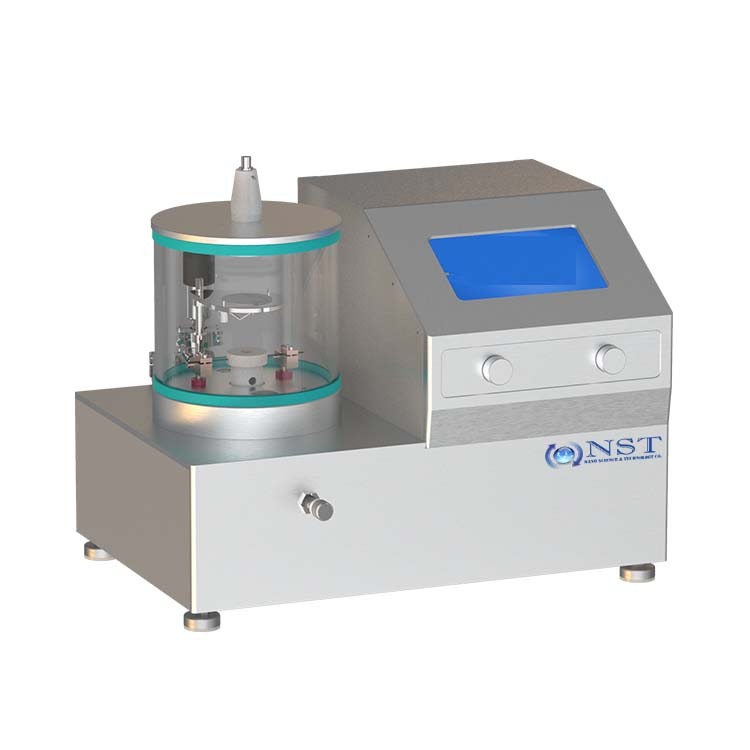

Small two-in-one coating machine NST-EVS180G-LV

2 × ₹650,000.00

Small two-in-one coating machine NST-EVS180G-LV

2 × ₹650,000.00 -

×

Single-target NST magnetron sputtering coater NST-MSP300S-NST

1 × ₹6,100,000.00

Single-target NST magnetron sputtering coater NST-MSP300S-NST

1 × ₹6,100,000.00 -

×

NST Lithium Battery Three Layer Vacuum Drying Oven

1 × ₹1,114,560.00

NST Lithium Battery Three Layer Vacuum Drying Oven

1 × ₹1,114,560.00 -

×

State-Of-The-Art High Temperature

1 × ₹9,288,000.00

State-Of-The-Art High Temperature

1 × ₹9,288,000.00 -

×

NST Laboratory 215L Larger 250C Digital Vacuum Oven (22x25x24" )

1 × ₹441,180.00

NST Laboratory 215L Larger 250C Digital Vacuum Oven (22x25x24" )

1 × ₹441,180.00 -

×

KF-10 HALF NIPPLE 40mm

1 × ₹550.00

KF-10 HALF NIPPLE 40mm

1 × ₹550.00 -

×

NST Small high vacuum two-in-one film coater

1 × ₹700,000.00

NST Small high vacuum two-in-one film coater

1 × ₹700,000.00 -

×

NST 1400°C Vacuum Atmosphere Elevating Lifting Furnace

1 × ₹685,000.00

NST 1400°C Vacuum Atmosphere Elevating Lifting Furnace

1 × ₹685,000.00 -

×

Three Target Heads Plasma Sputtering Coater NST-PSP180G-3TA

1 × ₹1,850,000.00

Three Target Heads Plasma Sputtering Coater NST-PSP180G-3TA

1 × ₹1,850,000.00 -

×

NST High vacuum magnetron sputtering coater

1 × ₹6,192,000.00

NST High vacuum magnetron sputtering coater

1 × ₹6,192,000.00

Subtotal: ₹30,420,810.00

There are no reviews yet.