-

×

NST-50L 200C Vacuum Dry Oven (16.3 X 13.5 X 14.5" ) With Digital Temperature Controller

1 × ₹450,000.00

NST-50L 200C Vacuum Dry Oven (16.3 X 13.5 X 14.5" ) With Digital Temperature Controller

1 × ₹450,000.00 -

×

10" Dia x 0.075" t x1.25" arbor SiC Abrasive Cutting Blades For Cut-off Saw- ST-SC1075

1 × ₹6,187.50

10" Dia x 0.075" t x1.25" arbor SiC Abrasive Cutting Blades For Cut-off Saw- ST-SC1075

1 × ₹6,187.50 -

×

NST Lithium Battery Vacuum Degassing Baking Oven For Industrial Use

1 × ₹774,000.00

NST Lithium Battery Vacuum Degassing Baking Oven For Industrial Use

1 × ₹774,000.00 -

×

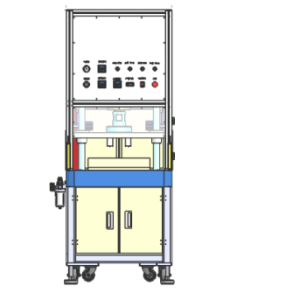

Customized Precision Die Cutter for Making Large Pouch Cell electrode Sheet upto 24"x24" - NST-600-C

1 × ₹371,005.00

Customized Precision Die Cutter for Making Large Pouch Cell electrode Sheet upto 24"x24" - NST-600-C

1 × ₹371,005.00 -

×

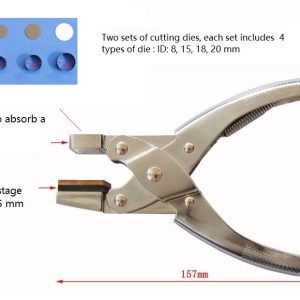

Hand-Held Disc Cutter with One Set of Ring Dies with ID 8,15, 18, 20 mm - NST-T-12

1 × ₹84,895.00

Hand-Held Disc Cutter with One Set of Ring Dies with ID 8,15, 18, 20 mm - NST-T-12

1 × ₹84,895.00 -

×

NST Laboratory 53L 250C Vacuum Drying Oven (16x13x14" )

1 × ₹399,000.00

NST Laboratory 53L 250C Vacuum Drying Oven (16x13x14" )

1 × ₹399,000.00 -

×

NST Laboratory 91L 250C Digital Vacuum Oven (18x18x18" )

1 × ₹312,000.00

NST Laboratory 91L 250C Digital Vacuum Oven (18x18x18" )

1 × ₹312,000.00 -

×

Thickness Diamond Dicing Blades - ST-EC-422-Blade

1 × ₹19,677.00

Thickness Diamond Dicing Blades - ST-EC-422-Blade

1 × ₹19,677.00 -

×

NST-UL Standard Compact RTP Furnace

1 × ₹850,000.00

NST-UL Standard Compact RTP Furnace

1 × ₹850,000.00 -

×

8" Dia x 0.05" t x1.25" arbor Alumina Abrasive Cutting Blade For NST-200 Auto Section Saw - ST-AL0801

1 × ₹2,470.00

8" Dia x 0.05" t x1.25" arbor Alumina Abrasive Cutting Blade For NST-200 Auto Section Saw - ST-AL0801

1 × ₹2,470.00 -

×

NST Lithium Battery Three Layer Vacuum Drying Oven

1 × ₹1,114,560.00

NST Lithium Battery Three Layer Vacuum Drying Oven

1 × ₹1,114,560.00 -

×

NST Single Stage Water Ring Vacuum Pump

1 × ₹103,000.00

NST Single Stage Water Ring Vacuum Pump

1 × ₹103,000.00 -

×

Compact & Precision Pneumatic Die Cutter with A Pair Die for Pouch Battery Research - NST-180SP

1 × ₹480,895.00

Compact & Precision Pneumatic Die Cutter with A Pair Die for Pouch Battery Research - NST-180SP

1 × ₹480,895.00 -

×

NST Small Roll To Roll Battery Electrode Continuous Coating Machine

1 × ₹928,800.00

NST Small Roll To Roll Battery Electrode Continuous Coating Machine

1 × ₹928,800.00 -

×

Three targets NST magnetron sputtering coater NST-MSP300S-3NST

1 × ₹8,668,000.00

Three targets NST magnetron sputtering coater NST-MSP300S-3NST

1 × ₹8,668,000.00 -

×

NST Laboratory 25L 200C Vacuum Oven (12x12x11" )

1 × ₹195,000.00

NST Laboratory 25L 200C Vacuum Oven (12x12x11" )

1 × ₹195,000.00 -

×

NST 1400°C CVD Tube Furnace With Gas Mixing & Pumping System

1 × ₹1,236,852.00

NST 1400°C CVD Tube Furnace With Gas Mixing & Pumping System

1 × ₹1,236,852.00 -

×

NST-3" two zones CSS furnace for rapid thermal processing

1 × ₹1,750,000.00

NST-3" two zones CSS furnace for rapid thermal processing

1 × ₹1,750,000.00 -

×

NST High vacuum magnetron sputtering coater

1 × ₹6,192,000.00

NST High vacuum magnetron sputtering coater

1 × ₹6,192,000.00 -

×

Dual-Target Magnetron Sputtering Coater NST-MSP300S-RFDC

1 × ₹8,049,600.00

Dual-Target Magnetron Sputtering Coater NST-MSP300S-RFDC

1 × ₹8,049,600.00 -

×

NST Two zones CSS furnace with rotating wafer holder

1 × ₹2,850,000.00

NST Two zones CSS furnace with rotating wafer holder

1 × ₹2,850,000.00 -

×

NST Programmable single chamber magnetron sputtering coater

1 × ₹1,500,000.00

NST Programmable single chamber magnetron sputtering coater

1 × ₹1,500,000.00

Subtotal: ₹36,337,941.50

-1.jpg)

There are no reviews yet.