-

×

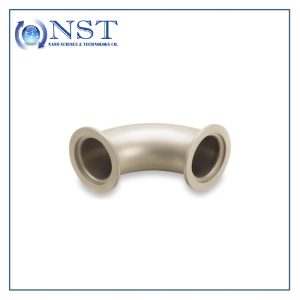

KF-50 ELBOW

1 × ₹1,500.00

KF-50 ELBOW

1 × ₹1,500.00 -

×

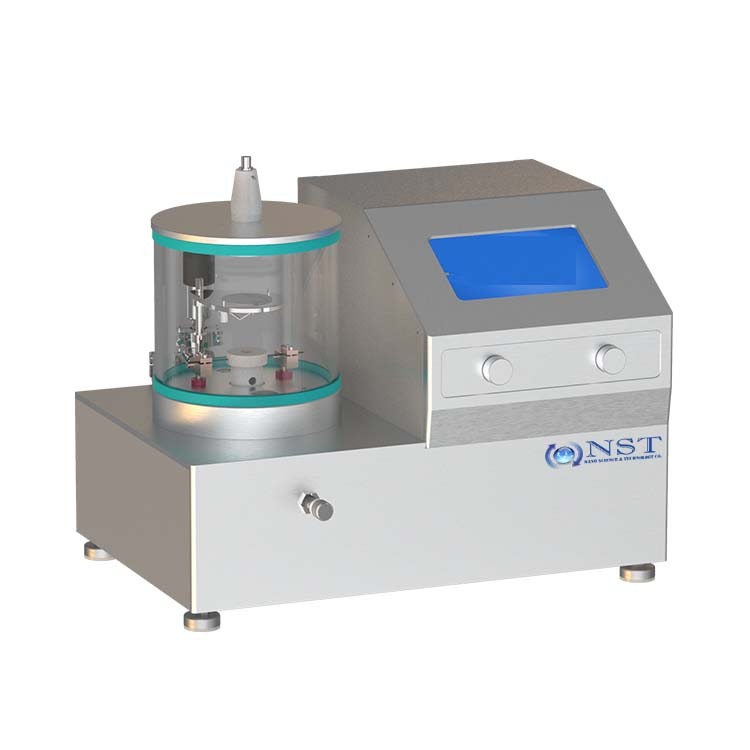

NST Small high vacuum two-in-one film coater

2 × ₹700,000.00

NST Small high vacuum two-in-one film coater

2 × ₹700,000.00 -

×

NST Small high vacuum thermal evaporation coater

1 × ₹1,100,000.00

NST Small high vacuum thermal evaporation coater

1 × ₹1,100,000.00 -

×

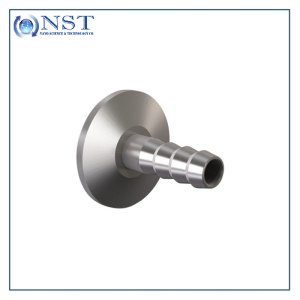

KF-50 FLANGE TO HOSE NOZZLE

1 × ₹1,050.00

KF-50 FLANGE TO HOSE NOZZLE

1 × ₹1,050.00 -

×

NST-150 Vacuum Pump Red Copper Spring Parts

1 × ₹2,500.00

NST-150 Vacuum Pump Red Copper Spring Parts

1 × ₹2,500.00 -

×

NST 1100°C Atmosphere Muffle Furnace

1 × ₹350,000.00

NST 1100°C Atmosphere Muffle Furnace

1 × ₹350,000.00 -

×

Three targets magnetron sputtering coater NST-MSP300S-2DC1RF

1 × ₹8,700,000.00

Three targets magnetron sputtering coater NST-MSP300S-2DC1RF

1 × ₹8,700,000.00 -

×

NST-Ultra-High vacuum thermal evaporation coater with four heating sources

1 × ₹4,953,600.00

NST-Ultra-High vacuum thermal evaporation coater with four heating sources

1 × ₹4,953,600.00 -

×

NST Single chamber magnetron sputtering system

1 × ₹2,350,000.00

NST Single chamber magnetron sputtering system

1 × ₹2,350,000.00 -

×

KF-40 ELBOW

1 × ₹1,250.00

KF-40 ELBOW

1 × ₹1,250.00 -

×

Three Target Heads Plasma Sputtering Coater NST-PSP180G-3TA

1 × ₹1,850,000.00

Three Target Heads Plasma Sputtering Coater NST-PSP180G-3TA

1 × ₹1,850,000.00 -

×

Dual-Target Magnetron Sputtering Coater NST-MSP300S-RFDC

1 × ₹8,049,600.00

Dual-Target Magnetron Sputtering Coater NST-MSP300S-RFDC

1 × ₹8,049,600.00 -

×

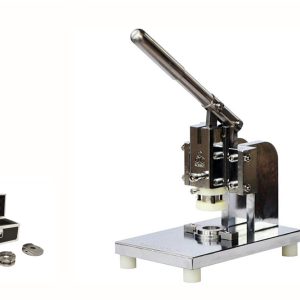

Compact Precision Disc Cutter with 4 Sets of Cutting Die (15, 19, 20 & 24 mm) - NST-T-07

1 × ₹296,385.00

Compact Precision Disc Cutter with 4 Sets of Cutting Die (15, 19, 20 & 24 mm) - NST-T-07

1 × ₹296,385.00 -

×

KF-40 SOCKET WELD FLANGE (SS-304)

1 × ₹750.00

KF-40 SOCKET WELD FLANGE (SS-304)

1 × ₹750.00 -

×

Precision Disc Cutter with Standard 16, 19, 20 Dia. Cutting Die & 3 - 24mm Optional - NST-T-10

1 × ₹371,005.00

Precision Disc Cutter with Standard 16, 19, 20 Dia. Cutting Die & 3 - 24mm Optional - NST-T-10

1 × ₹371,005.00 -

×

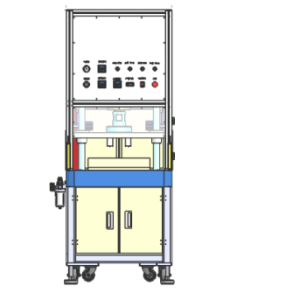

Customized Precision Die Cutter for Making Large Pouch Cell electrode Sheet upto 24"x24" - NST-600-C

1 × ₹371,005.00

Customized Precision Die Cutter for Making Large Pouch Cell electrode Sheet upto 24"x24" - NST-600-C

1 × ₹371,005.00 -

×

Three targets NST magnetron sputtering coater NST-MSP300S-3DC

1 × ₹8,668,000.00

Three targets NST magnetron sputtering coater NST-MSP300S-3DC

1 × ₹8,668,000.00 -

×

Hi-Throughput Pneumatic Disk Cutter with 15 & 19 mm Die for Coin Cell Separator & Electrode - NST-180SC

1 × ₹457,630.00

Hi-Throughput Pneumatic Disk Cutter with 15 & 19 mm Die for Coin Cell Separator & Electrode - NST-180SC

1 × ₹457,630.00 -

×

NST High vacuum magnetron sputtering coater

1 × ₹6,192,000.00

NST High vacuum magnetron sputtering coater

1 × ₹6,192,000.00 -

×

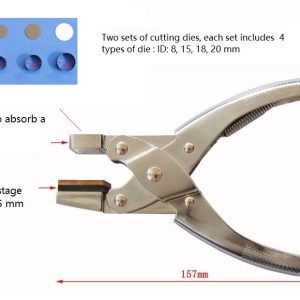

Hand-Held Disc Cutter with One Set of Ring Dies with ID 8,15, 18, 20 mm - NST-T-12

1 × ₹84,895.00

Hand-Held Disc Cutter with One Set of Ring Dies with ID 8,15, 18, 20 mm - NST-T-12

1 × ₹84,895.00

Subtotal: ₹45,201,170.00

There are no reviews yet.