-

×

4" Dia x 0.014"(0.35 mm) t x0.5" Arbor Edge Sintered Diamond Blade - ST-DB-153742-LD

2 × ₹13,489.00

4" Dia x 0.014"(0.35 mm) t x0.5" Arbor Edge Sintered Diamond Blade - ST-DB-153742-LD

2 × ₹13,489.00 -

×

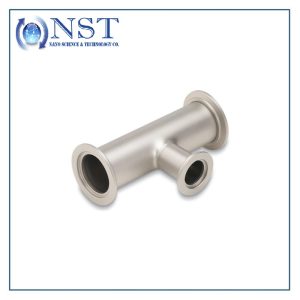

KF REDUCING TEE

1 × ₹2,300.00

KF REDUCING TEE

1 × ₹2,300.00 -

×

Through-Microscope Viewing for NST-202 Precision Diamond Wire Saw

1 × ₹241,315.00

Through-Microscope Viewing for NST-202 Precision Diamond Wire Saw

1 × ₹241,315.00 -

×

KF-25 CENTERING RING with VITON O-RING

1 × ₹750.00

KF-25 CENTERING RING with VITON O-RING

1 × ₹750.00 -

×

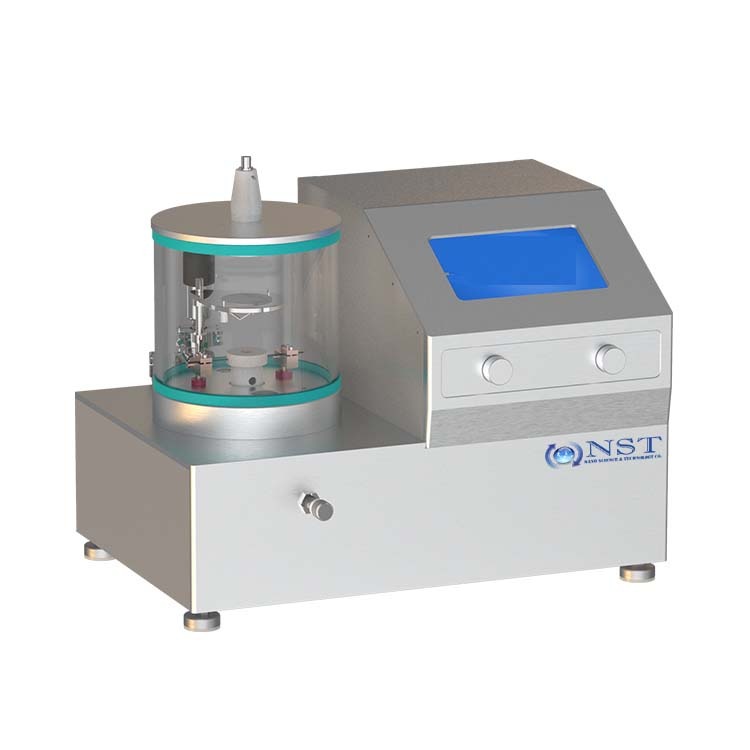

Professional Compact Turbo Pump Station (Oil Or Dry Backup Pump Optional)- NST-80

1 × ₹750,000.00

Professional Compact Turbo Pump Station (Oil Or Dry Backup Pump Optional)- NST-80

1 × ₹750,000.00 -

×

Turbo Pumping Station NST-620E

1 × ₹1,100,000.00

Turbo Pumping Station NST-620E

1 × ₹1,100,000.00 -

×

KF-10 CENTERING RING with Viton O-RING

1 × ₹450.00

KF-10 CENTERING RING with Viton O-RING

1 × ₹450.00 -

×

NST High Purity Aluminum Ring

1 × ₹11,000.00

NST High Purity Aluminum Ring

1 × ₹11,000.00 -

×

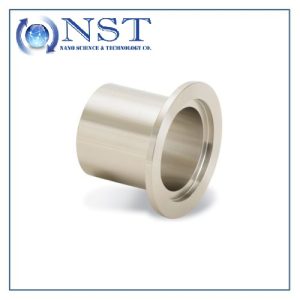

KF-10 HALF NIPPLE 40mm

1 × ₹550.00

KF-10 HALF NIPPLE 40mm

1 × ₹550.00 -

×

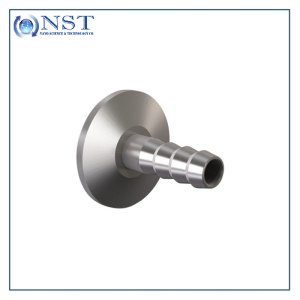

KF-10 FLANGE TO HOSE NOZZLE

1 × ₹450.00

KF-10 FLANGE TO HOSE NOZZLE

1 × ₹450.00 -

×

Dual-Target Magnetron Sputtering Coater

1 × ₹8,100,000.00

Dual-Target Magnetron Sputtering Coater

1 × ₹8,100,000.00 -

×

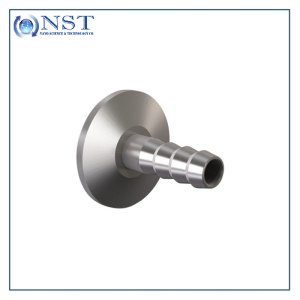

KF-16 FLANGE TO HOSE NOZZLE

1 × ₹550.00

KF-16 FLANGE TO HOSE NOZZLE

1 × ₹550.00 -

×

KF 4-WAY CROSS

1 × ₹2,500.00

KF 4-WAY CROSS

1 × ₹2,500.00 -

×

KF-16 CENTERING RING with VITON O-RING

1 × ₹650.00

KF-16 CENTERING RING with VITON O-RING

1 × ₹650.00 -

×

KF-25 CENTERING RING with NBR O-RING

1 × ₹550.00

KF-25 CENTERING RING with NBR O-RING

1 × ₹550.00 -

×

Small two-in-one coating machine NST-EVS180G-LV

1 × ₹650,000.00

Small two-in-one coating machine NST-EVS180G-LV

1 × ₹650,000.00 -

×

Turbo Pumping Station NST-80

1 × ₹1,100,000.00

Turbo Pumping Station NST-80

1 × ₹1,100,000.00 -

×

KF-16 ELBOW

1 × ₹850.00

KF-16 ELBOW

1 × ₹850.00 -

×

Replacement Water Splash Guard for covering

1 × ₹24,750.00

Replacement Water Splash Guard for covering

1 × ₹24,750.00 -

×

NST High Purity Aluminum Filament

1 × ₹10,500.00

NST High Purity Aluminum Filament

1 × ₹10,500.00 -

×

Vacuum Rapid Heated Pressing Furnace up to NST 1600℃

1 × ₹851,050.00

Vacuum Rapid Heated Pressing Furnace up to NST 1600℃

1 × ₹851,050.00 -

×

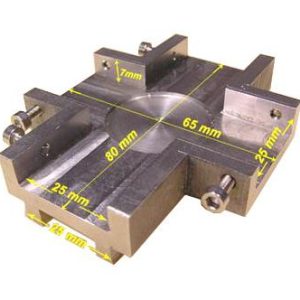

Precision Cross Mount Vise for EC400 dicing and 150 Low Speed

1 × ₹66,825.00

Precision Cross Mount Vise for EC400 dicing and 150 Low Speed

1 × ₹66,825.00 -

×

NST 1600°C Atmosphere Muffle Furnace

1 × ₹475,000.00

NST 1600°C Atmosphere Muffle Furnace

1 × ₹475,000.00 -

×

Thickness Diamond Dicing Blades - ST-EC-422-Blade

1 × ₹19,677.00

Thickness Diamond Dicing Blades - ST-EC-422-Blade

1 × ₹19,677.00 -

×

Fully Sintered Diamond Cutting Blades For Low Speed Saw - ST-DF0302

1 × ₹18,438.00

Fully Sintered Diamond Cutting Blades For Low Speed Saw - ST-DF0302

1 × ₹18,438.00 -

×

NST 1400°C CVD Tube Furnace With Gas Mixing & Pumping System

1 × ₹1,236,852.00

NST 1400°C CVD Tube Furnace With Gas Mixing & Pumping System

1 × ₹1,236,852.00 -

×

NST High vacuum magnetron sputtering coater

1 × ₹6,192,000.00

NST High vacuum magnetron sputtering coater

1 × ₹6,192,000.00

Subtotal: ₹20,883,985.00

There are no reviews yet.